Punching filter is a mesh product made by continuous punching of different metal plates on a CNC punching machine, and is mainly used to filter various items.

Filter perforated mesh is mainly used in various filtration industries, such as petroleum, food, medicine, mining, chemical and other fields.

Perforated filters have desirable advantages such as:

Good filtration performance, uniform surface filtration performance for the filtration particle size of 2-200um

Good corrosion resistance, heat resistance, pressure resistance and wear resistance;

Uniform pores and precise filtration accuracy;

Large flow per unit area;

Suitable for low temperature and high temperature environment;

It can be reused after cleaning without replacement.

The hole types that can be produced by the punching screen include round holes, oval holes, rectangular holes, square holes, rectangular holes, triangular holes, five-pointed star holes, hexagonal holes and other series of hole types. Different holes are selected according to the shape required for filtering. Type and size, generally a round hole.

The filter perforated mesh has a wide range of aperture options, and can be customized from 0.1mm to 200mm, which can meet the diameter requirements of any object.

The pitch of the filter mesh can be customized, from 1mm to 200mm, which greatly meets the needs of users who have a large demand for the opening ratio.

The smaller the pitch of the filter mesh, the faster the filtering speed, but the smaller the mesh strength.

The conventional filter size is 1m*2m, 1.2m*2.4m, and other size plates can also be customized according to user needs.

The thickness of the raw material sheet of the punching mesh is very rich, and the metal sheet of 0.1mm to 20mm can be manufactured.

The plate material can be galvanized iron plate, cold-rolled plate, hot-rolled plate, stainless steel plate, aluminum plate and other metal plates of different materials.

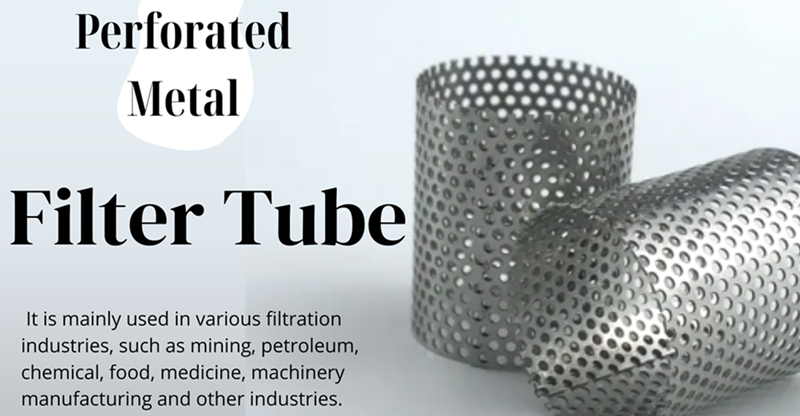

Filter perforated tube is a very typical perforated filter product.

Material: iron, stainless steel, material can be customized according to requirements.

Processing technology: CNC punch punching → cutting → roll → welding → → chamfering → surface treatment → forming

Perforated filter cartridges are cylindrical products made of perforated mesh. Mainly used in muffler, oil filter, filter element, sand control filter and other fields.

The perforated filter cylinder can be punched with metal plates of different materials such as iron plates, aluminum plates, and stainless steel plates according to customer requirements. After the punching is completed, it can be cut, rolled, welded, rounded, etc. for polishing.

If you have needs for perforated mesh in some aspects of filtration, please contact us.

As a high-quality Chinese manufacturer with more than 27 years of professional production experience, we will recommend the most suitable solution to you according to your use environment, so that you no longer need Confused about how to choose a reliable manufacturer.

CONTACT US

Are you still looking for a stable supplier? If you are still troubled by the communication of quality and details, please contact us—Anping Dongjie Wire Mesh.

Focusing on the wire mesh industry for more than 27 years, we have our own factory and professional team to escort your project!

0086-15930870079

NEED HELP?

Don’t hesitate to ask us something. Email us directly at admin@dongjie88.com or call us at 0086-15930870079.

GIVE US A CALL

As a high-quality Chinese manufacturer with more than 27 years of professional production experience, we will recommend the most suitable solution to you one-on-one according to your needs.

AVAILABLE AT 9AM TO 6PM

Post time: Mar-21-2023