What should be paid attention to when the punching mesh is sprayed? Let me introduce myself to you today.

Before starting to spray, there are several preparations to be aware of.

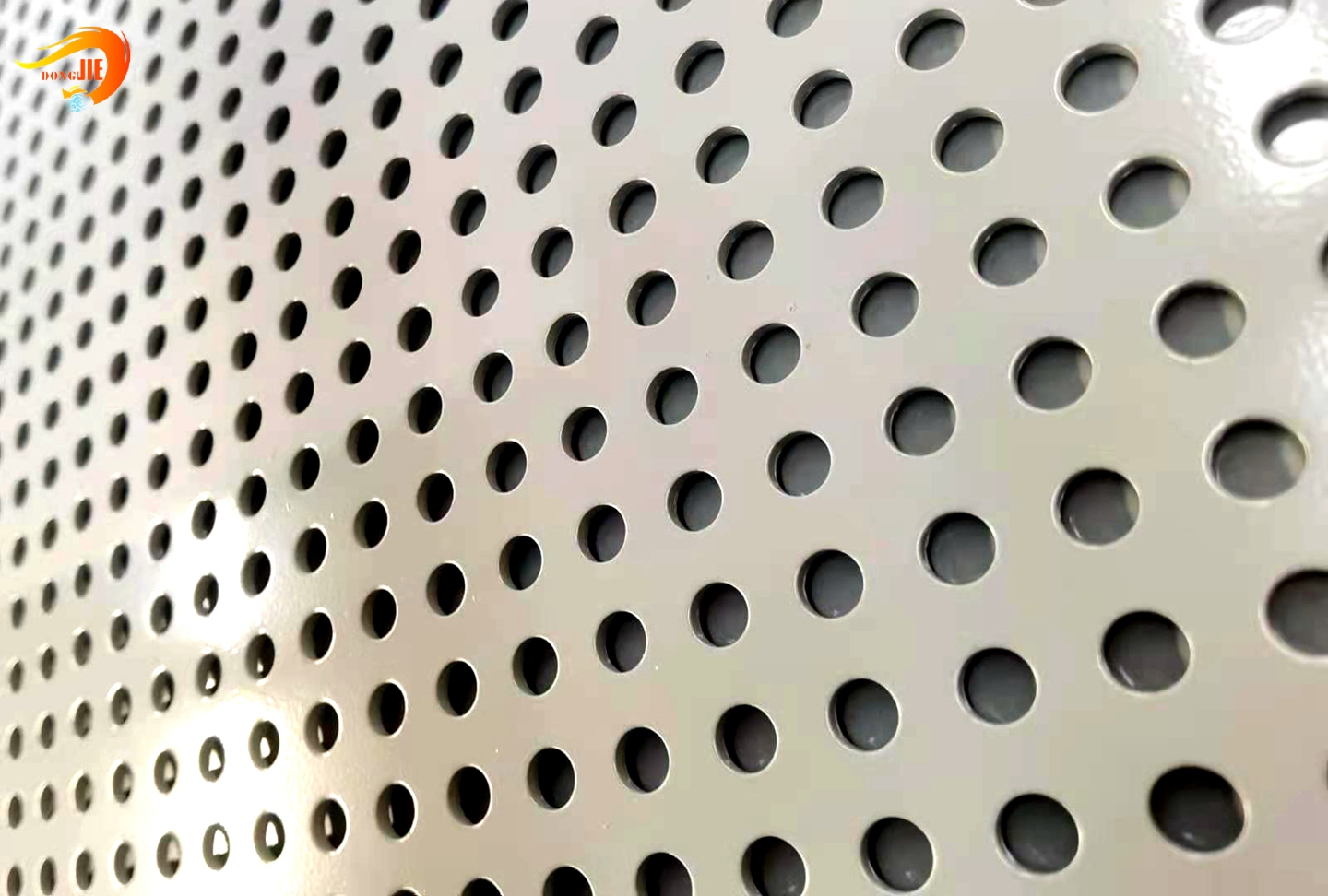

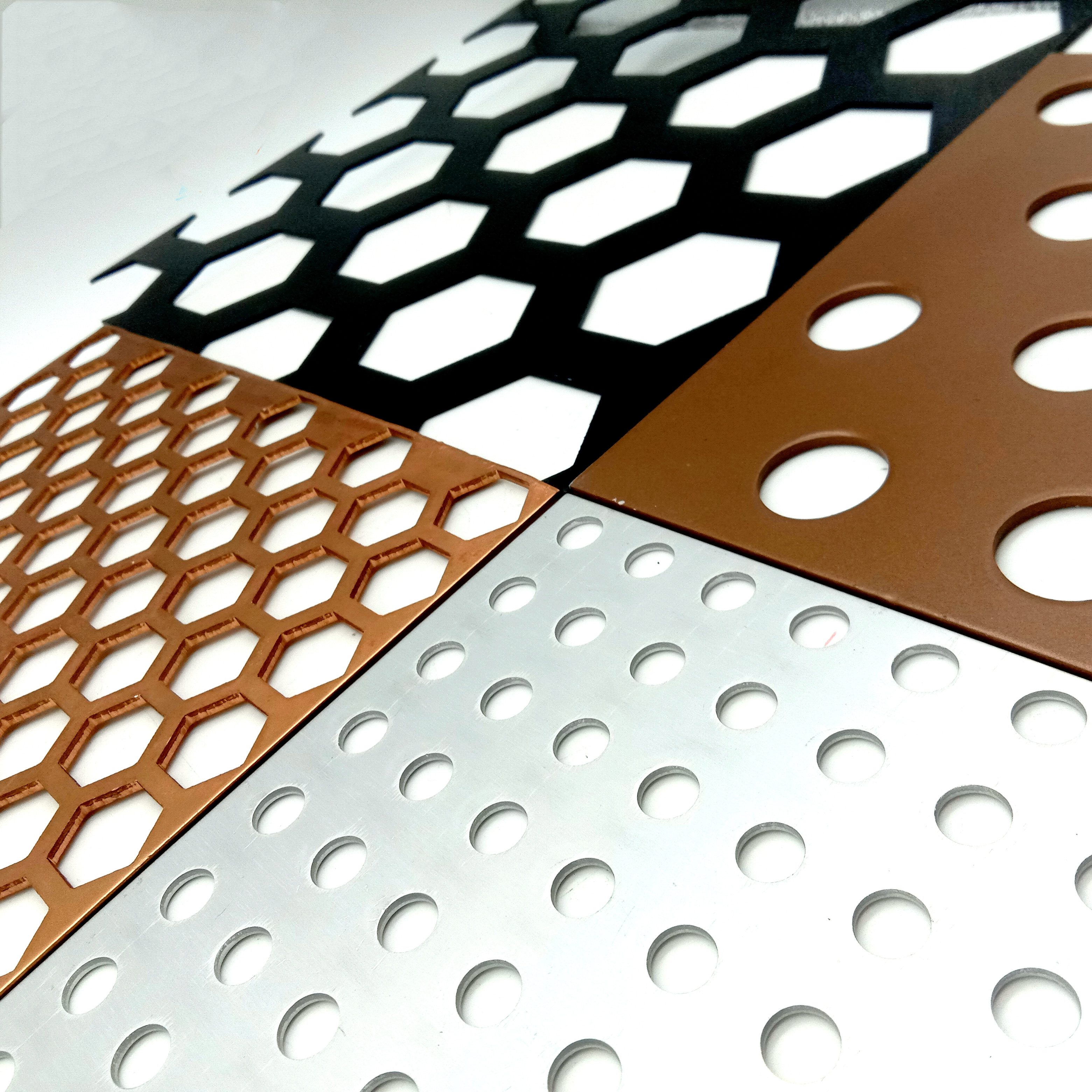

First of all, before the surface treatment of the perforated mesh, we have to ensure that the surface of the product is clean, such as: paint used for rust removal, rust generated on the surface, dust masked, etc., these substances can affect the perforated mesh. Therefore, it must be checked before spraying to ensure that the surface of the mesh is clean.

Secondly, the quality of the spray powder also needs special attention. It should be known that in the process of the spraying process, the final spraying effect of the punching net is closely related to the quality of the spraying powder. Therefore, if If we want the final spray and anti-corrosion treatment, we need better quality spray materials. If you are greedy for cheapness and use low-priced and low-quality spray powder, the product will have a poor appearance after treatment. Similarly, in the long-term application process, surface cracking will also appear. In response to this, Anping Dongjie Wire Mesh has been using high-quality spray powder to ensure product quality.

So after starting to spray, in process of spraying, we still need to pay attention to several issues.

For example, voltage. The voltage also needs our precise control, otherwise, it will greatly affect the quality of the spray. Generally speaking, the voltage values that people often use are in the range of 50 kV to 60 kV, and when the amount of powder spraying is large, the voltage value of 60 kW to 80 kW is used, but the frequency should not be too large, otherwise, It is very easy to cause safety hazards. In the ordinary spraying process operation, the voltage value of about 30 kV to 50 kV is the most ideal and suitable voltage value.

Spraying distance: This depends on the distance between the meshes. Generally speaking, in the field of perforated mesh product spraying, the spraying distance used by people ranges from 100 mm to 300 mm, which is perforated mesh. The most ideal spray spacing value for the product.

Spraying on the corners: When spraying the surface of the perforated mesh, we try to spray the corners first, and after the corners have been treated, we will then process other parts. When necessary, the angle and voltage standard of the spray tool can also be adjusted.

Of course, these issues have already been considered for our Anping Dongjie Wire Mesh. If your product needs to be sprayed, we can provide you with a very good experience, so you are welcome to communicate with us with your plan.

Contact Me

WhatsApp/WeChat :+8613363300602

Email:admin@dongjie88.com

Post time: Sep-26-2022