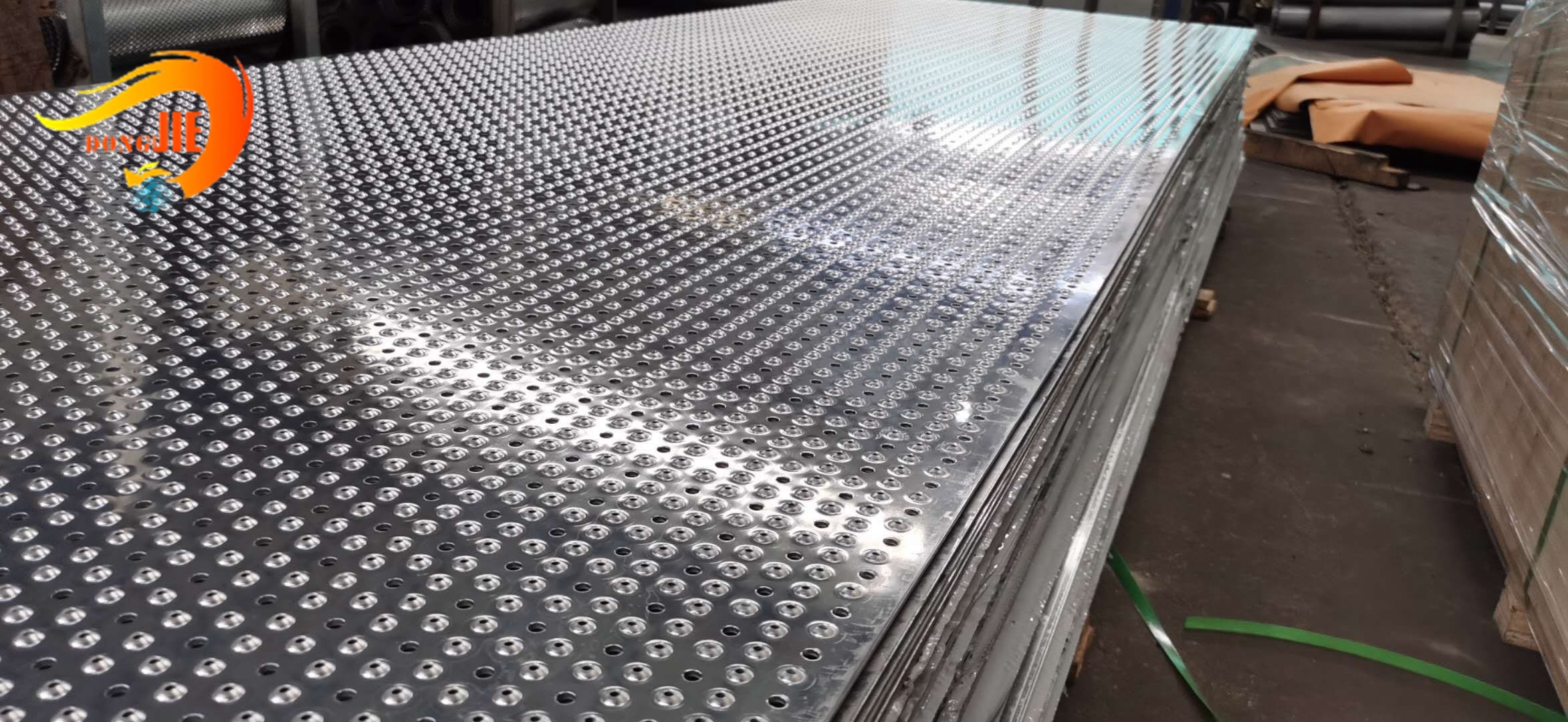

From feeding material to processing to finished product, each step of punching mesh is very important, but the quality of punching mesh depends on the quality of metal plate, but what kind of punching plate can be the best choice for punching mesh What about the material? Let me analyze it for you:

1. Good stamping performance: The stamping performance of the punching plate refers to the adaptability of the sheet to various stamping processing methods. The stamping processing method is a processing method in which metal is plastic, so the material is required to have good plasticity. For materials with good plasticity and a large degree of deformation required to be allowed, the number of stamping processes and intermediate annealing times of the sieve plate can be reduced. For the separation process, it is also required to have a certain plasticity, and the yield limit of the material is required to be slightly higher, so as to obtain a higher section quality after punching.

2. Good surface quality: For materials with good surface quality, the workpiece is not easy to break when the sieve plate is punched, and the waste products are reduced; the mold is not easy to scratch, the service life is improved, and the surface quality of the workpiece is good. Therefore, it is generally required that the surface of the stamping material is smooth and neat, without defects such as scale, cracks, rust spots, and scratches.

3. Comply with the thickness tolerance stipulated by the national standard: the mold gap is determined according to the material thickness, so the material thickness tolerance should meet the specified standards. Otherwise, the thickness tolerance is too large, which will affect the quality of the workpiece and may cause damage to the mold and equipment.

Post time: Jan-28-2023