Why should the perforated metal mesh be sprayed?

Do you know why it is necessary to carry out the step of plastic spraying after the punching and forming, because if the surface is sprayed after processing the punching and forming, it can not only play an aesthetic role, but also have anti-corrosion and protection functions.

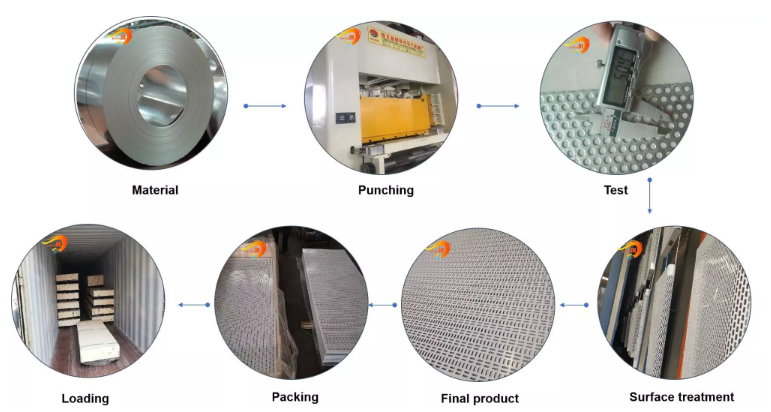

The principle of punching molding spray technology: the plastic powder is charged by high-voltage electrostatic equipment, and under the action of the electric field, the paint is sprayed onto the surface of the punching net, and the powder will be evenly adsorbed on the surface of the perforated metal mesh to form a powdery coating.

The powder coating is leveled and solidified after being baked at high temperature, and the plastic particles will melt into a layer of dense final protective coating with different effects; firmly attached to the surface of the punching net.

The punching forming net is sprayed with electrostatic powder coating, which uses an electrostatic generator to charge the plastic powder with electricity. It is adsorbed on the surface of the iron plate and baked at 180°C to 220°C to let the powder melt and attach to the metal surface.

Punching forming mesh spray plastic treatment, no pollution to the environment, no harm to the human body.

The characteristics of plastic spraying are bright appearance, higher strength and mechanical strength, higher corrosion resistance and wear resistance. The colors of spraying are white, blue, green, silver, yellow and so on.

If you need it, just click the button below.

Post time: Jan-30-2023