OEM Galvanized Filter Mesh Filter End Caps for Dust Cartridge

OEM Galvanized Filter Mesh Filter End Caps for Dust Cartridge

The filter end cap mainly serves to seal both ends of the filter material and support the filter material. It stamped into various shapes as needed from the steel sheet. The end cap is generally stamped into a groove on which the end face of the filter material can be placed and an adhesive can be placed, and the other side is bonded with a rubber seal to function to seal the filter material and seal the passage of the filter element.

-Production description-

|

Filter End Caps |

|

|

Outer Diameter |

Inside Diameter |

|

200 |

195 |

|

300 |

195 |

|

320 |

215 |

|

325 |

215 |

|

330 |

230 |

|

340 |

240 |

|

350 |

240 |

|

380 |

370 |

|

405 |

290 |

|

490 |

330 |

The filter end cap mainly serves to seal both ends of the filter material and support the filter material. The filter end caps are stamped into various shapes as needed from the steel sheet.

-Applications-

-Why choose us-

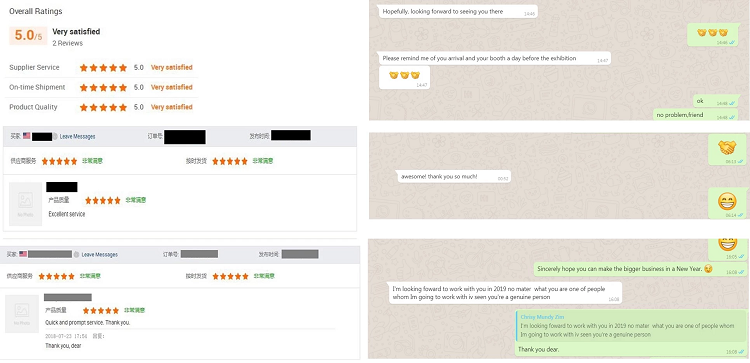

Anping Dongjie Wire Mesh Products Co., Ltd., located in Anping, China is a specialized manufacturer for the development, design, and production of expanded metal mesh, perforated metal mesh, decorative wire mesh, and stamping parts for decades.

Dongjie has adopted ISO9001:2008 Quality System Certificate, SGS Quality System Certificate, and modern management system.

As always stuck into "Quality Proves Strength, Details Reach to Success", Dongjie achieves high acclaim in the old and new customers.

1. 25 years' experience in producing filter end caps.

2. Accurate size according to customer requirements

3. Ensure the filters have a longer life with excellent heat and chemical resistance.

4. Effectively improve the capacity of the filter material.

5. Various exist molds to save your cost.

6. Qualified raw materials with certifications to make the filter caps.

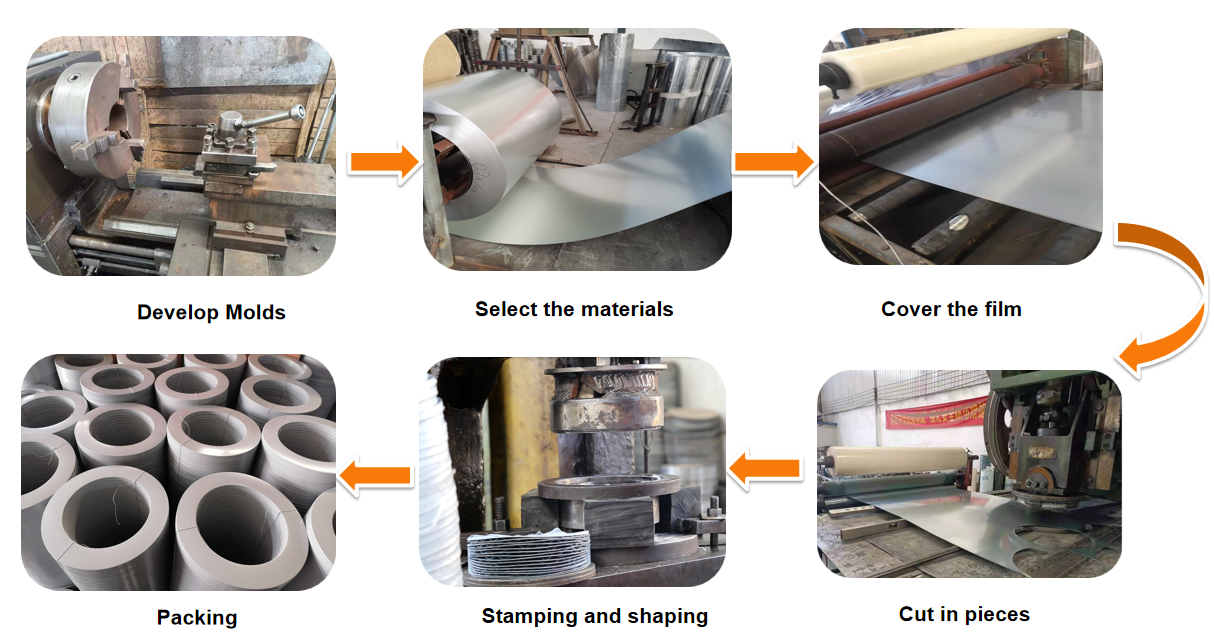

-Production process-

Galvanized steel is coated with zinc oxide to prevent rusting since the chemical compound takes far longer to corrode than steel. It also changes the steel’s appearance, giving it a rugged look. Galvanization makes the steel stronger and harder to scratch.

The materials used to produce filter end caps include galvanized steel, anti-fingerprint steel, stainless steel, and many other materials. The filter end caps have various shapes as different needs. Each of the three materials has its own advantages.

Anti-fingerprint steel is a kind of composite coating plate after fingerprint-resistant treatment on the surface of galvanized steel. Because of its special technology, the surface is smoother and it is non-toxic and environmentally friendly.

Stainless steel is material that anti-corrosion to the air, vapor, water and acid, alkali, salt, and other chemical corrosion media. The common kinds of stainless steel include 201, 304, 316, 316L, etc. It has no rust, long service life, and other characteristics.

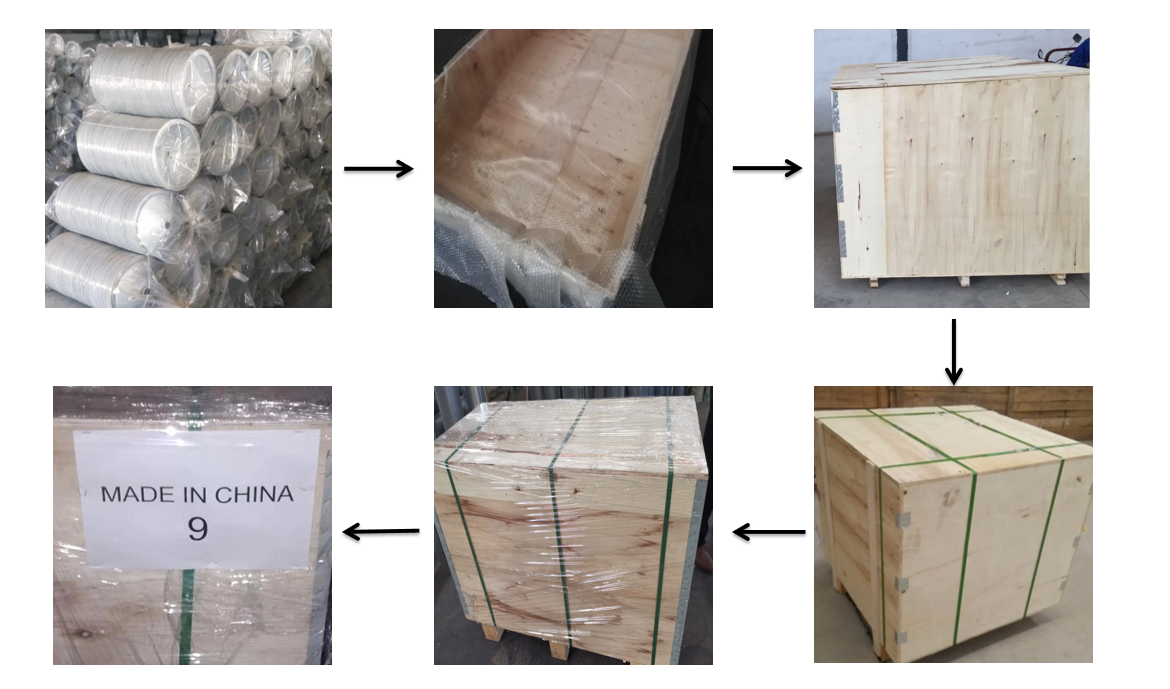

-Packing&delivery-

ANPING DONGJIE WIRE MESH PRODUCTS CO., LTD

Q1: Are you a manufacturer or a trader?