Carbon filtering is a method of filtering that uses a piece of activated carbon to remove contaminants and impurities and utilize chemical adsorption. When the material adsorbs something, it attaches to it by chemical attraction. The huge surface area of activated charcoal gives it countless bonding sites. When certain chemicals pass the carbon surface, they will attach to the surface and are trapped. When used for air purification, the filter can be simply installed up high in the ventilation system, they can also operate as individual units which is more convenient.

Activated carbon filter element is made of high quality fruit shell carbon and coal-based activated carbon as raw materials, supplemented by edible grade binder, using high and new technology, processed by special process. It integrates adsorption, filtration, interception and catalysis. It can effectively remove organic residue chlorine and other radioactive substances in water, and has the function of decolorization and odor removal. This is an ideal new product produced in the liquid and air purification industry.

Advantage:

▲Anti-corrosion

▲Low pressure loss

▲Quick bayonet installation design, lightweight and convenient

▲ Strong adsorption capacity, high removal efficiency and reliable performance

▲Easy installation and maintenance, low operating costs

▲The adsorption medium can be replaced, and the metal shell can be reused

Features of activated carbon include:

|

(1) Has a capacity for virtually any vapor contaminant; it will adsorb some of almost any vapor.

(2) Has a large capacity for organic molecules, especially solvents. (3) Will adsorb and retain a wide variety of chemicals at the same time. (4) Has an extremely large capacity to catalyze destroy ozone of the smog. (5) Works well under a wide range of temperature and humidity conditions. (6) Adsorbs odors and chemicals preferentially to moisture. It is not a desiccant and will release moisture to adsorb chemicals. (7) Can be used as a carrier of one material to attract and hold or react with another material. |

|

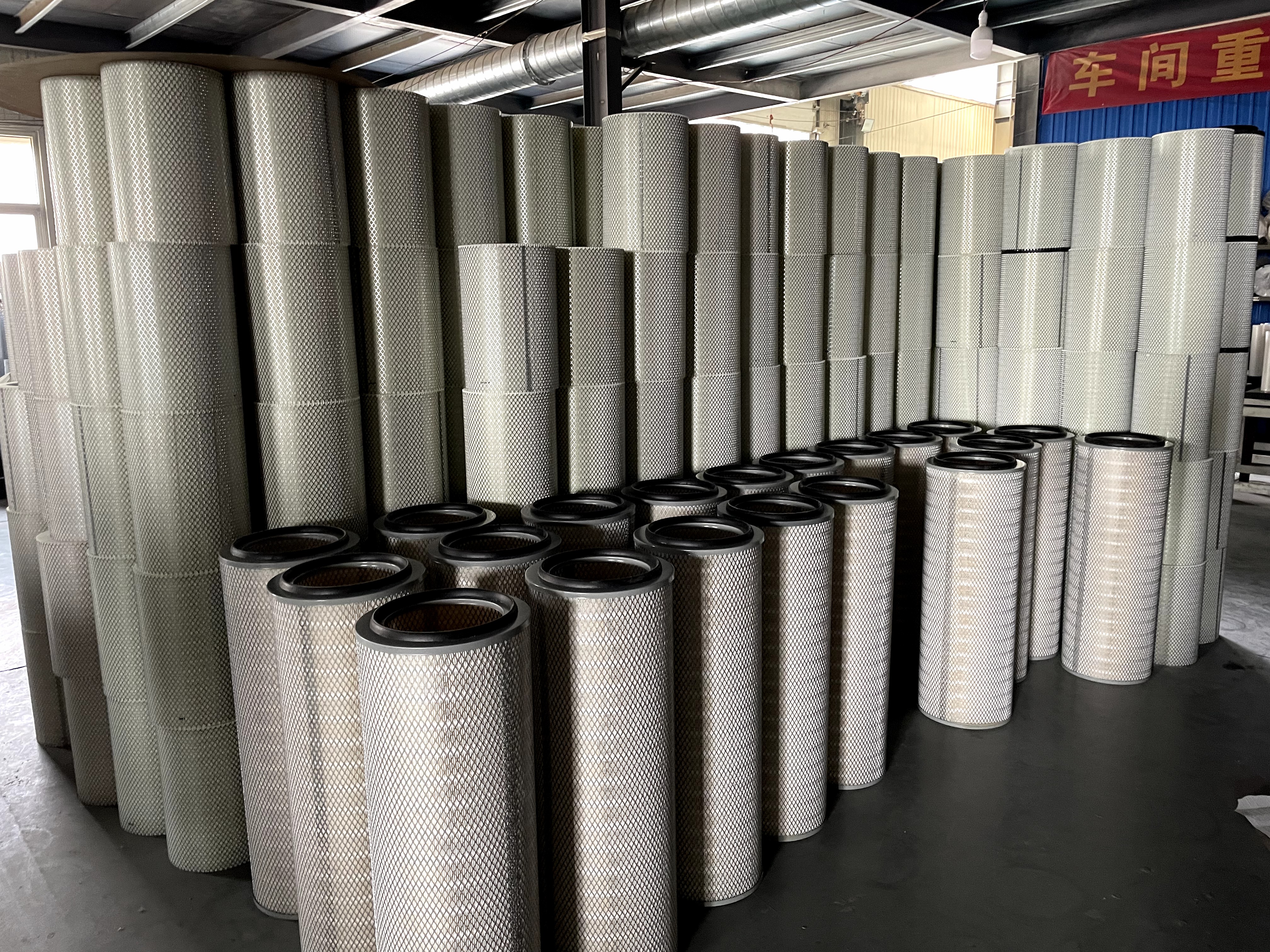

We can produce a variety of durable standard-sized filter cylinders and boxes, high-performance in-line filters, and customized filters for various applications.

As a manufacturer of activated carbon filter elements, we fully control the quality of the activated carbon media used in our filters, and we can customize it according to your specific use. We are specialized in the most commonly used filters as standard and always have stock in our warehouse, we are also experts in manufacturing customized filters according to customers’ requirements.

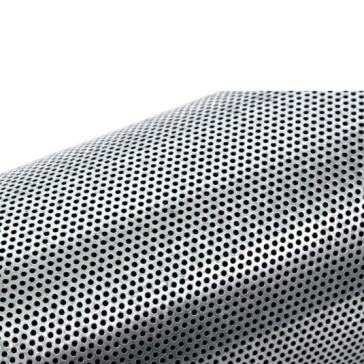

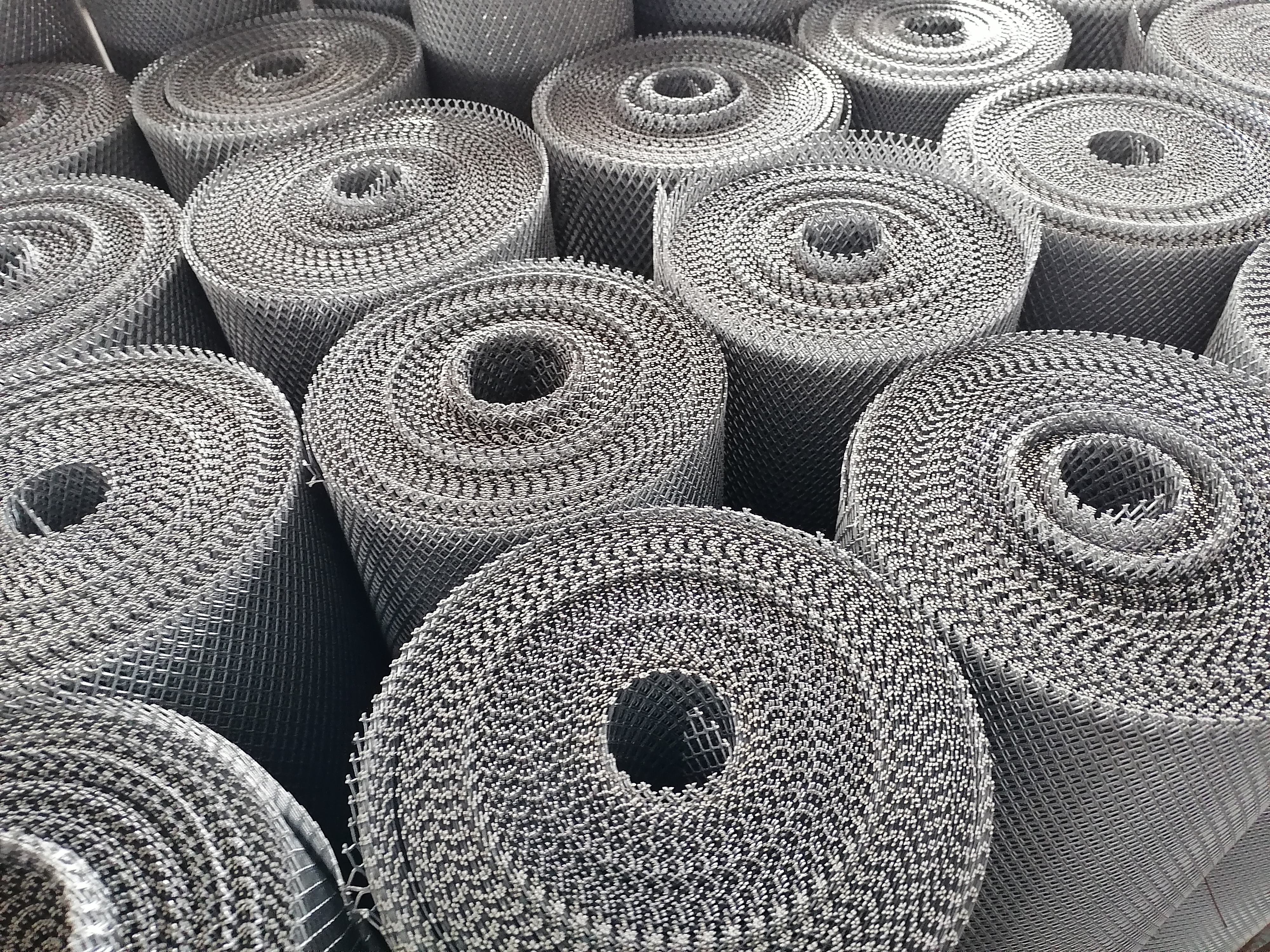

There are some pictures of activated carbon filters for reference.

|

|

|

|

|

|

|

Charcoal Canister Type |

Height |

Material |

Outer Diameter |

Loading Quantity of Carbon |

Carbon Bed Thickness |

|

(mm) |

(mm) |

(liters) |

(mm) |

||

|

DJ-1000S |

250 |

Galv. Steel |

145 |

2.9 |

26 |

|

DJ-1000E |

250 |

Stainless Steel |

145 |

2.9 |

26 |

|

DJ-2600S |

450 |

Galv. Steel |

145 |

4.3 |

26 |

|

DJ-2600E |

450 |

Stainless Steel |

145 |

4.3 |

26 |

|

DJ-2600K |

450 |

Galv. Steel |

145 |

4.3 |

26 |

|

DJ-3500S |

600 |

Galv. Steel |

145 |

5.7 |

26 |

|

DJ-3500E |

600 |

Stainless Steel |

145 |

5.7 |

26 |

|

DJ-3500k |

600 |

Galv. Steel |

145 |

5.7 |

26 |

Applications

Activated carbon filter element is suitable for purification and solution in semiconductor, electronic device, printed circuit board, electroplating industry, food, and beverage industry and other sectors.

Applicable to the following industries:

1. Electronics, electric power industry: pure water, gas, electric transfer liquid, printing line, etc.

2. Chemical industry, petrochemical industry: solvent, paint, magnetic slurry, detergent, and so on.

3. Pharmaceutical industry: hospital water, pharmaceutical injection, and so on.

4. Food industry: food, beverage, drinking water, alcohol, etc.

ANPING COUNTY DONGJIE WIRE MESH PRODUCTS CO., LTD

Anping Dongjie Wire Mesh Products Factory is founded in 1996 with 5000sqm areas. We have more than 100 professional workers and 4 professional workshops: expanded metal mesh workshop, perforated workshop, stamping wire mesh products workshop, molds made, and deep-processing workshop.

Our Skills & Expertise

We are a specialized manufacturer for the development, design, and production of expanded metal mesh, perforated metal mesh, decorative wire mesh, filter end caps and stamping parts for decades. Dongjie has adopted ISO9001:2008 Quality System Certificate, SGS Quality System Certificate, and a modern management system.

If you need it, just click the button below.

Post time: Mar-29-2023