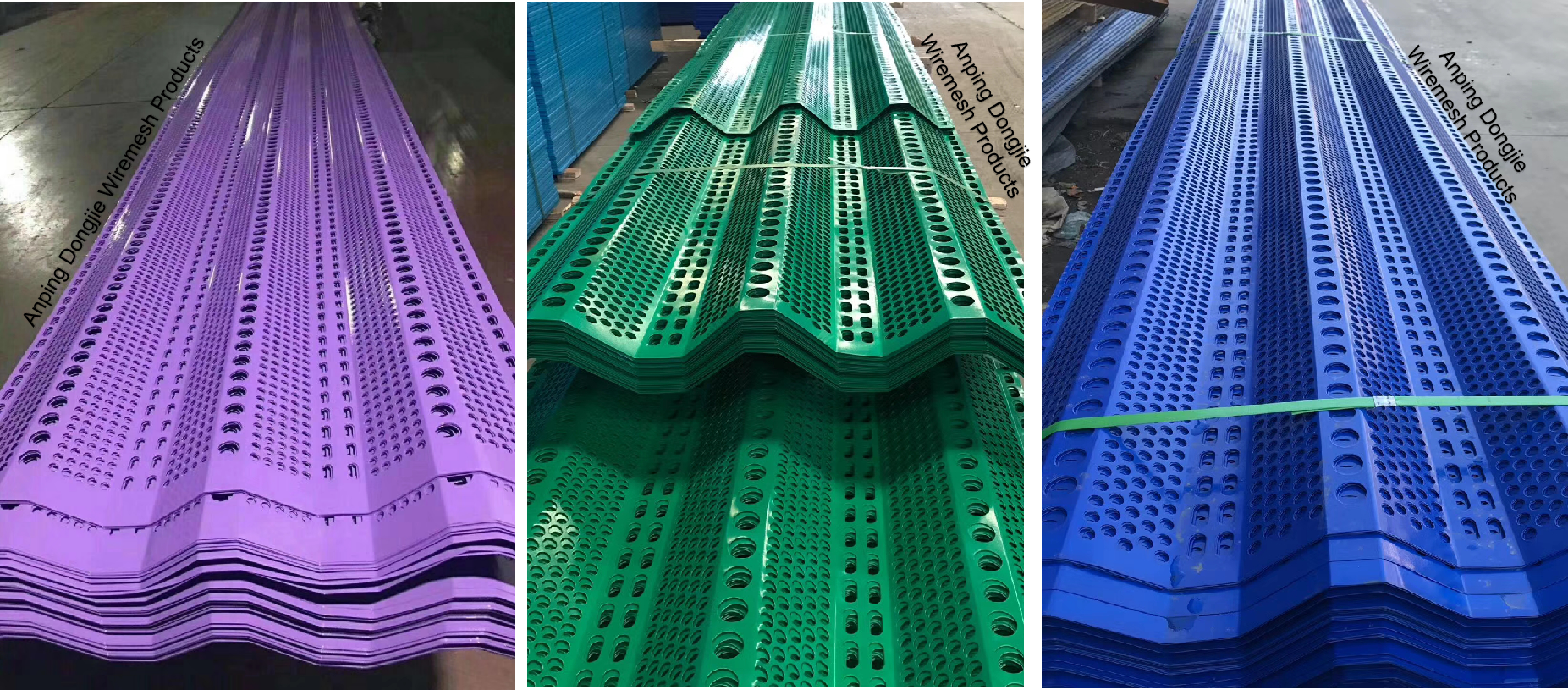

(1) Use ordinary cold-rolled steel plates as the basic material. The plate thickness is 0.5mm-1.5mm. It is punched and formed by CNC equipment, and then the surface is treated with double-sided high-voltage electrostatic powder spraying for anti-corrosion treatment.

(2) Use galvanized steel plate as the basic material. The thickness of the plate is 0.5mm-1.5mm. It is punched and formed by CNC equipment, and then the surface is treated with double-sided high-voltage electrostatic powder spraying for anti-corrosion treatment.

(3) Use color-coated steel plates as the basic material. The plate thickness is 0.5mm-1.5mm, which is punched and formed by CNC equipment. No surface treatment is required.

(4) Use galvanized steel plate as the basic material. The thickness of the plate is 0.5mm-1.5mm, which is punched and formed by CNC equipment. No surface treatment is required.

(5) Use stainless steel plates as the basic material. The plate thickness is 0.5mm-1.5mm. It is punched and formed by CNC equipment. No surface treatment is required.

Windproof and dust suppression nets generally use a punching process and then a plastic dipping process. After relevant tests and experiments on polymer composite materials, the optimal length of the windshield is 3-3.2m, and the optimal width is 250-300mm. If it is too long, it will easily produce a certain degree of deflection. If it is too wide, each windshield will bear more wind. The pressure is large, which affects the strength and service life of the windshield. The windshield and dust suppression net has a service life of 15 to 20 years. Operating environment temperature: -40 ℃; + 80 ℃.

The connection between the windshield and the bracket is fixed with screws and pressure plates. After engineering applications in recent years, the comprehensive dust suppression effect of windproof and dust suppression nets is very obvious. The comprehensive dust suppression effect of a single-layer windproof and dust-suppressing net can reach about 65% to 75%, and the comprehensive dust-suppressing effect of a double-layer windproof net can reach about 75% to 85%. Therefore, the setting of windproof and dust suppression nets effectively protects the environment.

There is still a lack of understanding of the dynamic characteristics (including frequency, vibration shape and damping) of the windproof and dust suppression net structure and the vibration response characteristics of the windproof net structure under the action of wind load, which brings more uncertainty to the safety of the windproof net structure design. The dynamic characteristics and wind vibration response of mesh structures are topics to be studied. The frequency domain analysis method is to convert the universal wind speed spectrum or the wind pressure time history measured by the wind tunnel test directly into the wind pressure spectrum through Fourier transformation, obtain the structural dynamic response spectrum through the power transfer coefficient, and integrate the response spectrum through the stochastic theory Obtain the dynamic response of the structure.

Post time: Dec-15-2023