Etching mesh is to use chemical etching method to produce high-precision mesh with complex shape and metal mesh with concave convex pattern that can not be completed by various machining on various metal sheets according to the designed geometric figures and patterns.

Etching technology advantages

1. This technology improves the traditional metal processing method.

2. This technology can process concave and convex metal products through data, charts, designs and complex columns.

3. Etching technology can be used to make holes and various forms.

Etched stencil technology is widely used in integrated circuits, fluorescent displays, precision filtration, micro-electrodes, etc.

Features of etching excellent plate processing:

1. Good acid resistance, alkali resistance and corrosion resistance.

2. The surface finish is high, no surface treatment is required, and the maintenance is convenient and simple.

3. High rigidity, strong wear resistance and durability.

4. High temperature oxidation resistance, good stainless steel raw materials can withstand high temperature of 800 degrees without deformation.

5. It is easy to process and can be etched, stamped and welded; it can also be used for subsequent aesthetic processing such as surface electroplating, oil injection, and coloring.

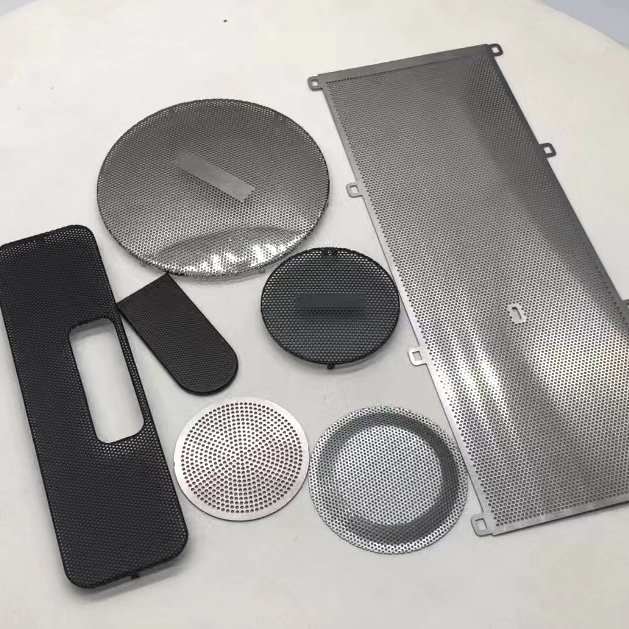

Application of etching technology

(1) Precision filters, filter plates, filter cartridges, and filters for petroleum, chemical, food, and pharmaceutical applications;

(2) Metal leakage plates, cover plates, flat pins, lead frames, and metal substrates for the electronics industry;

(3) Precision optical and mechanical plane parts, spring parts;

(4) Friction plates and other concave-convex plane parts;

(5) Metal signs and metal decorative plates with complex patterns and exquisite handicrafts.

Post time: Nov-21-2023