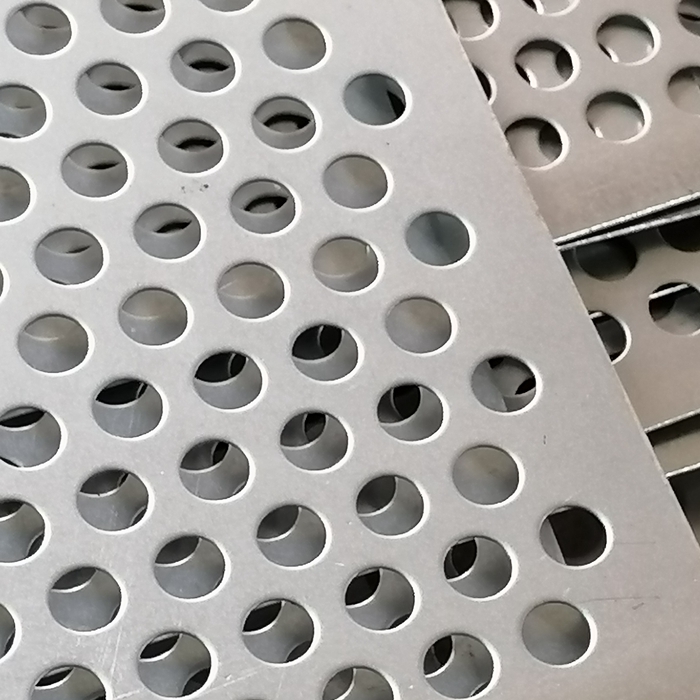

Everyone knows that most of the processing substrates of performed metal mesh are metal plates (iron plates, stainless steel plates, aluminum plates, etc.). The finished products are generally metal in color. However, in order to adapt to the needs of different applicable environments and extend the service life of the product, many customers require that the punched mesh must undergo a series of surface treatments to complete the processing and use. The surface-treated products not only become more beautiful in color, but also have a greatly improved service life, thereby reducing costs. General surface treatment can be roughly divided into the following categories:

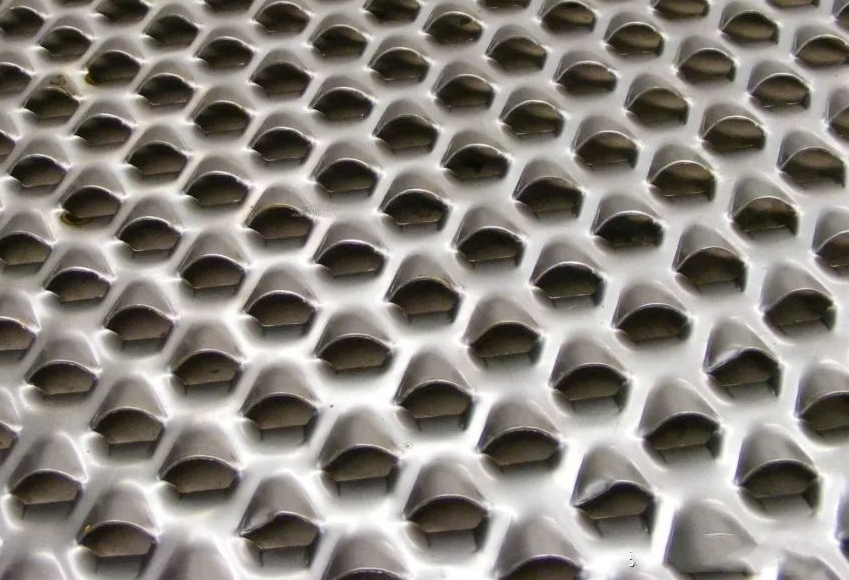

1. Performed metal mesh galvanizing:

Galvanizing is divided into electro-galvanizing (cold plating) and hot-dip galvanizing. The dense basic zinc carbonate film generated on the zinc surface is used to achieve the purpose of preventing rust, corrosion and beauty. Electro-galvanizing uses the principle of electrolysis to allow zinc ions to adhere to the surface of the perforated mesh to form a coating. The cyanide in the galvanizing electrolyte contains highly toxic substances. The characteristic of electro-plating is that the zinc layer is fine, tight and glossy. Hot-dip galvanizing is to subject the material to be plated to anti-oxidation (anti-oxidation free radical), annealing (annealing) and other treatments before putting it into zinc liquid for high-temperature hot-dip plating. The advantage of hot-dip galvanizing is that the zinc layer covers the entire surface and is more durable. Strong, can maintain a service life of 20-50 years (generally used in hot plate punching mesh).

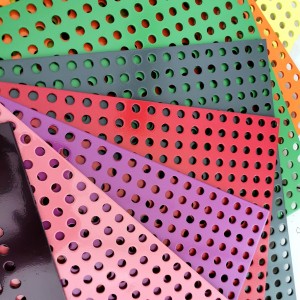

2.Perforated metal mesh dipped in plastic:

The punching net is heated to melt the plastic powder on the surface of the board. The heating time and temperature will affect the thickness of the plastic layer. Dip plastic can enhance the waterproof, anti-rust, and anti-erosion properties of the product, and a variety of colors can be selected to make the product more attractive. Beautiful and more ornamental (generally rarely used, it is easy to block the mesh).

3. Anodizing of perforated metal mesh:

The perforated mesh is placed in the corresponding acidic electrolyte as an anode. Under certain conditions and the action of electric current (Electron flow), it is decomposed to form a thin layer of aluminum oxide (Al), which not only improves the performance of the perforated mesh. The hardness and wear resistance, as well as corrosion resistance, also give it good insulating properties and heat resistance (generally used in aluminum plate punching mesh).

Post time: Dec-11-2023