1. Mold design is required in the production of perforated metal mesh. Everyone must know that the quality of the mold determines the quality of the product to a large extent. Therefore, in recent years, our factory has invested a lot of money in this area, which has also significantly improved our molding capabilities.

2. After the mold is manufactured, it needs to be punched. Our factory has advanced CNC equipment that can punch high-quality products.

3. Cutting: Our factory is a newly introduced laser cutting machine, which can cut the entire roll of boards into the size you need.

4. Leveling: We use a leveling machine to restore the deformed punched plate to its original flat state. Steel plates with a thickness of 0.8-12mm can be leveled.

5. Cleaning: The punching process requires the use of lubricants, but we also have a degreasing process that can remove traces on its surface and make the orifice plate look clean.

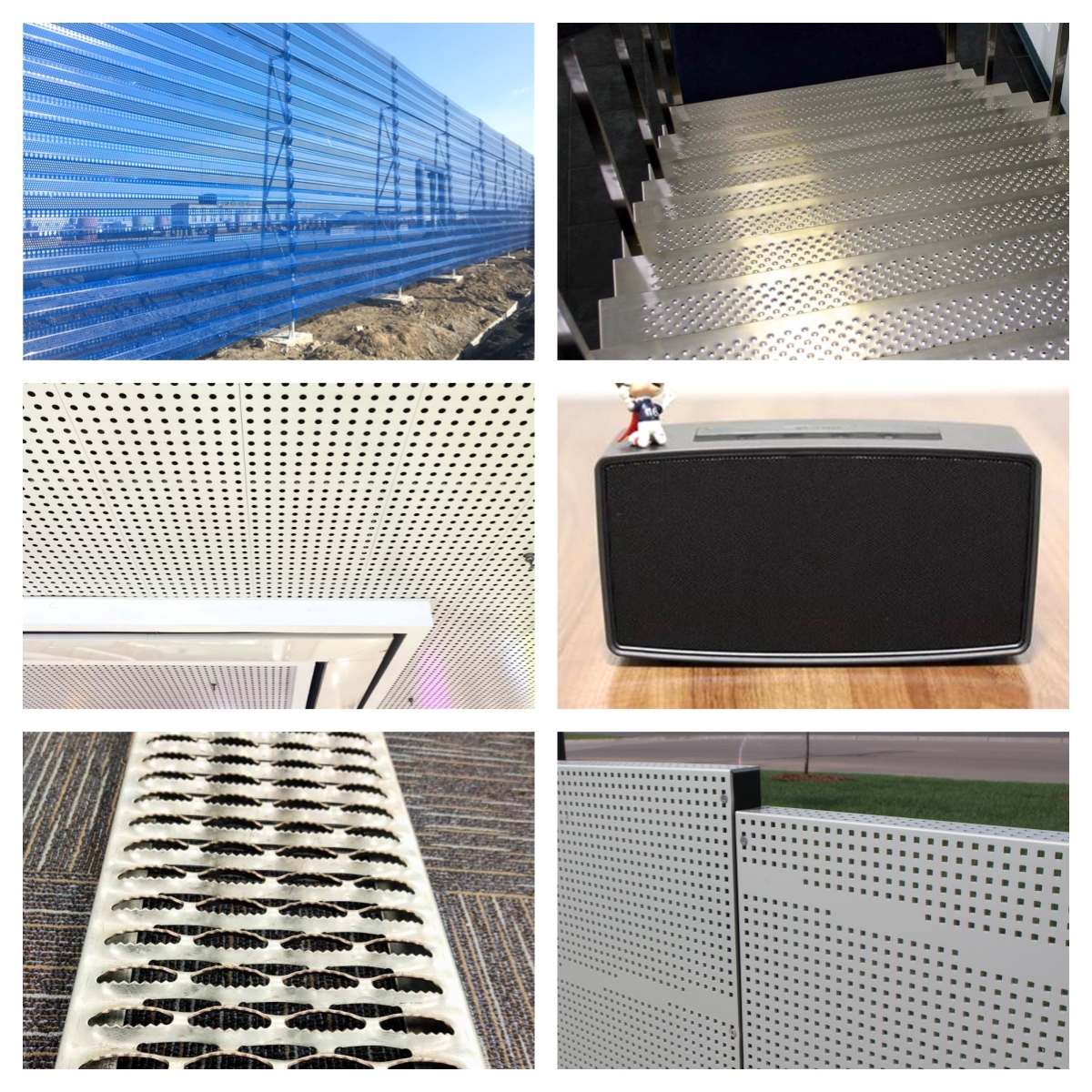

6. Surface treatment: According to customer requirements, the surface of the plate can be treated with electro-galvanizing, hot-dip galvanizing, electrostatic spraying, frosting, anodizing, fluorocarbon spraying, etc.

Everyone knows that metal will be oxidized and rust in the air. Stainless steel is made by adding a certain amount of chromium, nickel, titanium and other elements to the steel. When the chromium content exceeds 12%, it can play the role of stainless steel. We often see stainless steel products in humid and warm environments. For materials that are prone to rust, we need to choose surface treatments. Surface treatments include galvanizing, plastic spraying, plastic dipping, spray painting, etc. Their use can effectively isolate them. The air oxidizes the metal surface and isolates it from the air, which plays a fast and effective anti-corrosion effect. It can also make our perforated metal mesh products more beautiful and durable.

Post time: Sep-15-2023