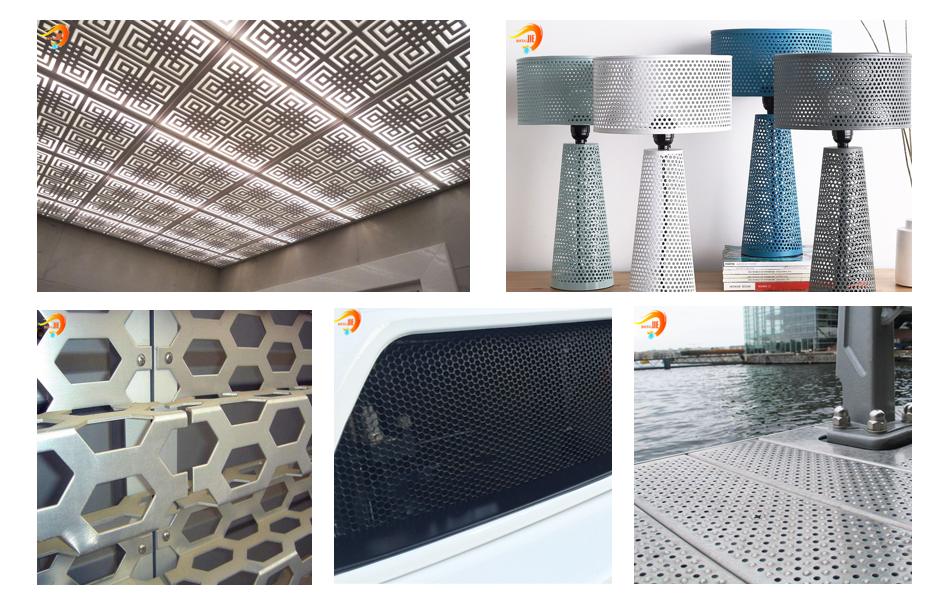

Perforated metal mesh is a metal product processed by a stamping process and is characterized by precise hole diameter and shape, as well as good mechanical strength and durability. This kind of metal mesh is widely used in many fields, such as construction, agriculture, industry and home decoration, etc.

In the field of construction, punched metal mesh can be used to make the support system of building formwork to provide a stable support structure; it can also be used as part of the exterior wall insulation system to enhance the thermal insulation performance of the wall. In addition, it can also be used to make soundproof walls, anti-theft windows, stair handrails, etc.

In the agricultural field, perforated metal mesh is often used as a covering material for greenhouses to help regulate climate conditions in the greenhouse; it can also be used for livestock fences to protect crops from animals.

In the industrial field, punched metal mesh can be used in filtration systems, such as oil-water separators and air filters, to remove impurities in liquids or gases; it can also be used to manufacture protective covers for mechanical equipment to prevent operators from coming into contact with moving parts and ensure production Safety.

In the field of home decoration, punched metal mesh can be used to make screens, partitions and decorations, adding a sense of spatial hierarchy while providing a certain degree of privacy protection.

The materials of punched metal mesh usually include stainless steel, carbon steel, aluminum alloy, etc. The selection of these materials depends on its end use and required performance requirements. Stainless steel perforated mesh is often used in high-end decoration and food industry due to its excellent corrosion resistance and aesthetics; carbon steel perforated mesh is widely used in construction and industrial fields due to its higher strength and lower cost; Aluminum alloy punched mesh is often used in outdoor decoration and aerospace fields because of its light weight and corrosion resistance.

The hole size, shape and arrangement of the punched metal mesh can be customized according to specific needs to meet different application scenarios. For example, punched metal mesh with small pores is suitable for fine filtration, while larger pores are suitable for ventilation and protection.

Overall, punched metal mesh has become an indispensable part of modern industry and life with its diverse applications, customizable features, and excellent performance. Whether it is the support of building structures, the protection of agricultural production, the filtration and protection of industrial production, or even the beautification of home decoration, punched metal mesh plays an important role. With the advancement of technology and changes in market demand, the types and functions of punched metal mesh will continue to be innovated and improved to adapt to more extensive and complex application scenarios.

Post time: Apr-19-2024