Dongjie wire mesh Products factory to provide you with hexagonal punching metal plate processing design.

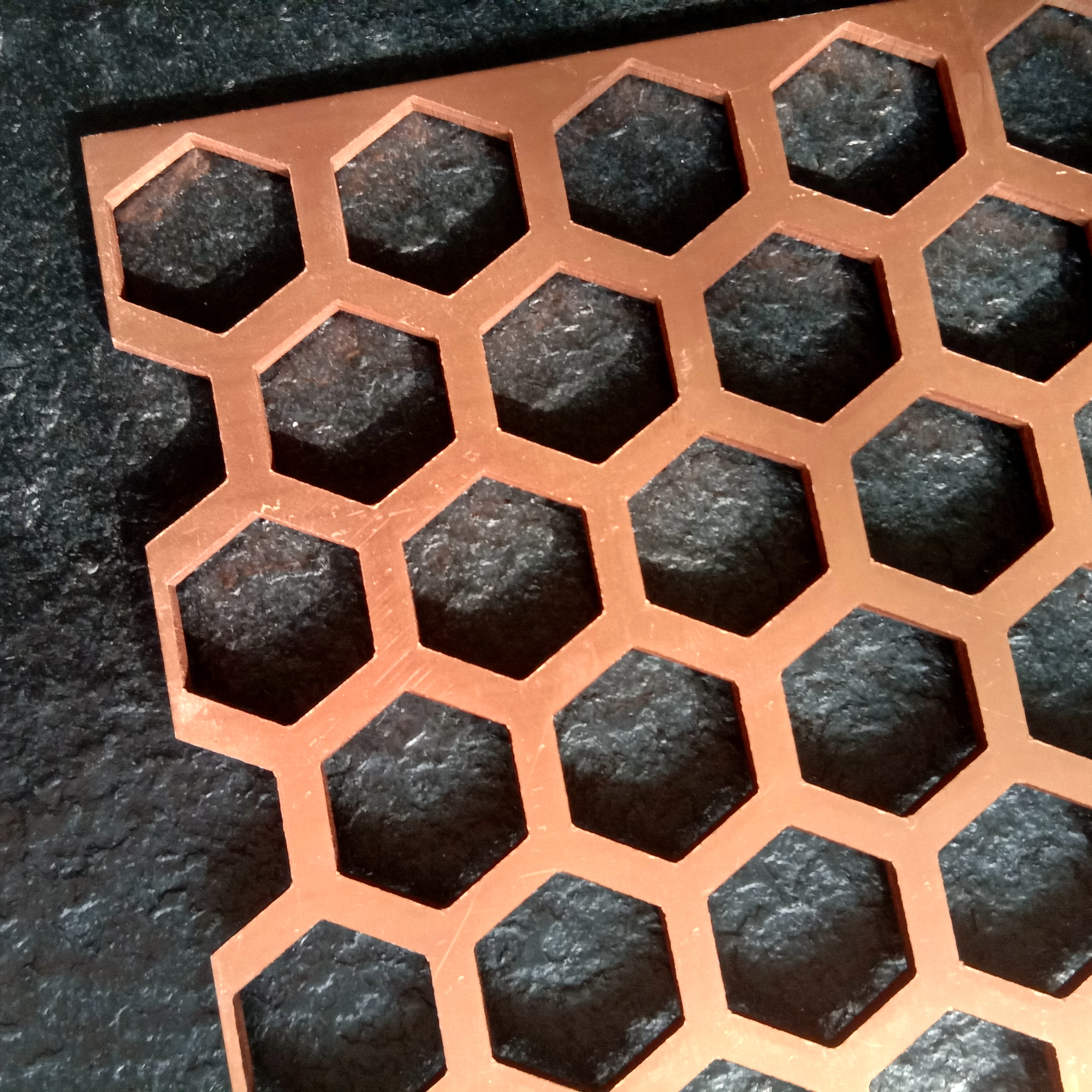

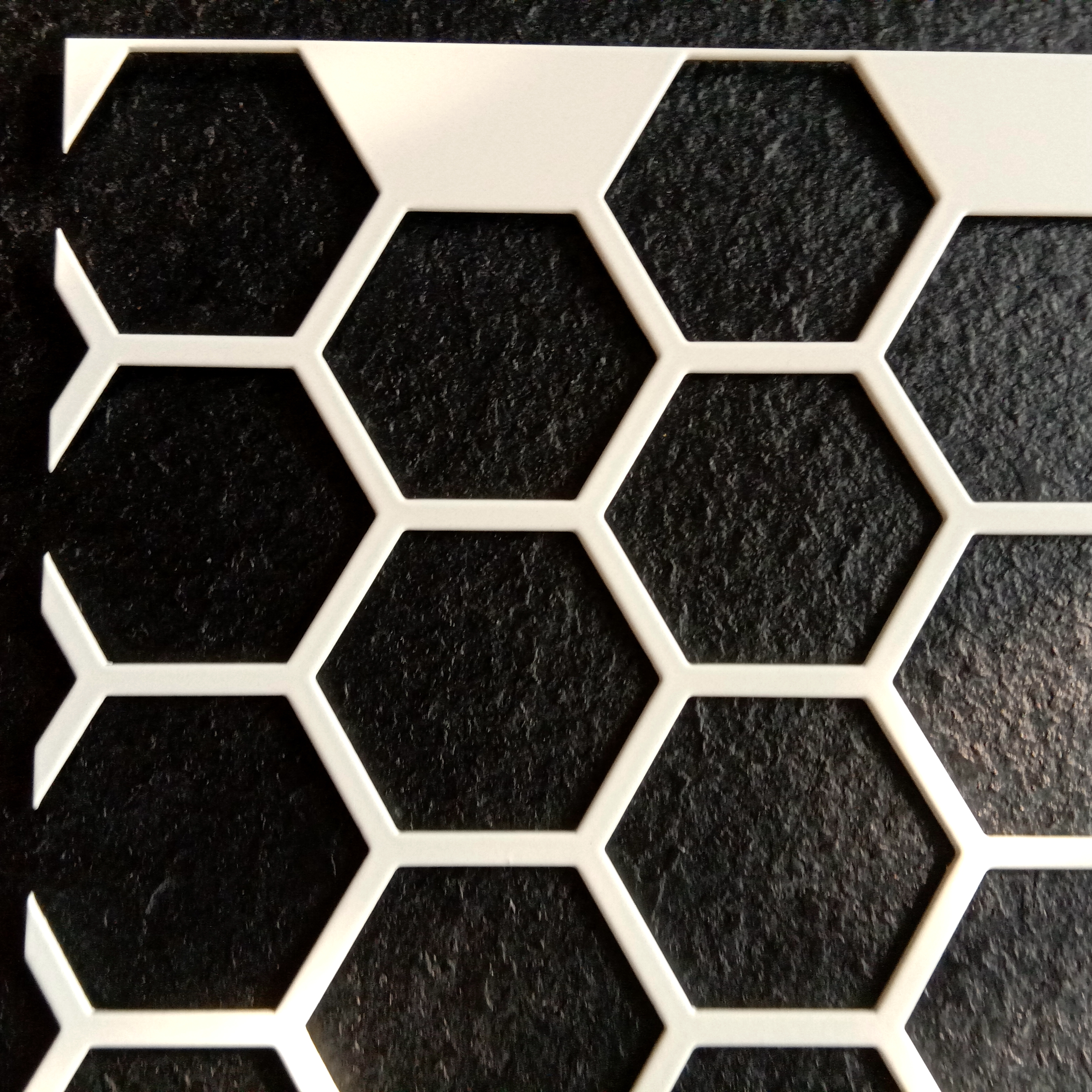

Hexagonal hole punching metal plate is a kind of punching metal plate series, mainly because of the hexagonal hole shape rushed out on the plate.

Hexagonal screen is usually made of galvanized steel plate, stainless steel plate, copper plate, aluminum plate, nickel plate, alloy plate as raw materials, through the stamping die.

Dongjie wire mesh is pleased to provide you with the processing and production of punching grid manufacturers at wholesale prices.

Dongjie wire mesh Products factory to provide you with hexagonal punching metal plate processing design.

Hexagonal hole punching metal plate is a kind of punching metal plate series, mainly because of the hexagonal hole shape rushed out on the plate.

Hexagonal screen is usually made of galvanized steel plate, stainless steel plate, copper plate, aluminum plate, nickel plate, alloy plate as raw materials, through the stamping die.

Dongjie wire mesh is pleased to provide you with the processing and production of punching grid manufacturers at wholesale prices.

Hexagonal hole perforated metal mesh materials:

Stainless steel, aluminum, low carbon steel plate, galvanized plate, aluminum-magnesium alloy plate, copper plate, nickel plate, PVC, etc.

Production and characteristics of hexagonal hole perforated metal mesh:

Stamped and extended; divided into punching mesh, expanded metal, aluminum mesh, sieve plate, perforated plate, horn mesh, etc.

The use of hexagonal hole perforated metal mesh:

Widely used in interior or exterior decoration, the hexagonal perforated mesh is mainly used for decoration, ceiling, metal curtain wall, fence protection, etc. Hexagonal perforated mesh is a new material in the decoration industry. With its own unique properties, the usage rate in the decoration industry is increasing year by year. The hexagonal perforated mesh has a beautiful appearance, solid overall structure, and tensile strength several times greater than that of expanded metal. Corrosion resistance, light weight per square meter, ventilation, light transmission, sound absorption, high toughness, easy construction, and low cost.

Also widely used in chemical machinery, pharmaceutical equipment, food and beverage machinery, cigarette machinery, harvesters, dry cleaning machines, ironing tables, silencers, refrigeration equipment (central air conditioning) speakers, handicraft production, papermaking, Various industries such as hydraulic fittings and filtration equipment.

The production process of the hexagonal hole perforated metal mesh:

1. Mould

The punching process starts with a precise mold design. We believe that the quality of the mold determines the quality of the product to a large extent. Therefore, in recent years, we have invested a lot of money in this area, which has significantly improved our mold-making capabilities.

2. Punching

The numerical control equipment we have can punch high-quality products, with a daily output of 2000 square meters, and the thickness of the sheet that can be punched is between 0.1mm-10mm.

3. Cut

Cut from the whole roll of the board to the size you need.

4. Trim

If the edge of the board in the production process exceeds the tolerance range you require, our skilled technicians can help you remove the extra edge according to your requirements.

5. Flattening

We can use a flattening machine to restore the deformed punching plate to its original flat state. Steel plates with a thickness of 0.4mm-5mm can be leveled.

6. Clean

The punching process requires the use of lubricant, but we also have a degreasing process to remove traces on its surface and make the orifice plate look clean.

7. Production molding and deep processing.

In addition to customers, we can also provide you with a series of subsequent processing, including leveling, cutting, labeling, packaging, degreasing, deburring, forming, annealing, painting, electroplating, welding, polishing, bending, forming Volume and so on.

8. Surface treatment

Processes such as punching, leveling and cutting will cause incompleteness of the surface of the sheet, but this incompleteness is acceptable in general industrial products. If you have special requirements, we will take preventive measures such as powder spraying or painting, electro-galvanizing, hot-dip galvanizing, anodizing, and other additional measures.

Dongjie Wire Mesh Products Co., Ltd. is a production-oriented enterprise integrating development, design, production, sales, and integration. The company produces more than one hundred specifications of perforated mesh. The quality has passed the quality inspection of Chinese wire mesh products and fully meets the national standard. With quality standards, terminal manufacturers provide one-to-one services to users, and sales prices are more reasonable. In order to meet market demand, the company is the first domestic company to independently design and produce perforated mesh with any length of external dimensions and no waste of materials, which makes the application of hexagonal perforated nets more flexible and convenient, and reduces the cost of the construction party.

Material: aluminum plate, cold plate, stainless steel, galvanized steel, copper, etc.

Hole shape: hexagonal

Aperture: 25x10mm 40x10mm 50x20mm 60x20mm 80x30mm 100x40mm 150x50mm 200x50mm

Thickness: 2.0-30.00mm

Surface: spray paint, dipping, galvanized

Price: USD 2.3-47

Uses: Hexagonal perforated metal is widely used in decoration, ceiling hanging panels, metal curtain walls, mechanical protection, factory fences, coal mines, power plants, school fences, and other industries.

Contact Me

WhatsApp/WeChat :+8613363300602

Email:admin@dongjie88.com

Post time: Dec-15-2022