1. The origin of fingerprint resistant plate

Fingerprint resistant processing was originally developed to meet the requirements of users in the field of home appliances. In the production process of home appliances, due to the needs of the process, many parts are touched by workers many times, and the sweat stains on the hands of workers will form pollution on the surface of the parts, affecting the appearance, so the research and development of fingerprint resistant plates.

2. Features of fingerprint resistant plate

In addition to some special processes, fingerprint resistant technology early use is the coating containing hexavalent chromium, with more and more stringent environmental regulations, hexavalent chromium technology is gradually replaced by trivalent chromium technology and chromium-free technology, modern chromium-free technology not only has the corrosion resistance of chromium-containing technology, but also has the versatility of chromium-containing technology does not have. Widely used in home appliances, electronics and construction markets.

3. Type of fingerprint resistant plate

One is the passivation of galvanized sheet, and then on the passivation film coated organic coating (fingerprint resistant film), the coating method is mainly roller coating.

The other is to add organic resin and colloidal silica in the passivation solution of galvanized steel, and form a composite coating with corrosion resistance and fingerprint resistance on the surface of galvanized steel through the passivation tank. The coating methods are mainly electrolytic coating and roll coating. At home and abroad, the first process is generally used to produce fingerprint resistant plates.

The traditional fingerprint resistant plate is based on electrogalvanized plate as the substrate. With the continuous improvement and development of hot galvanizing technology and process, the surface quality of hot galvanized sheet has reached the same degree as that of electrogalvanized sheet, and hot galvanized sheet has low price and better corrosion resistance, so hot galvanized sheet as fingerprint resistant substrate is gradually becoming the mainstream. In addition, 2007 has a variety of properties in one (such as fingerprint resistance, electrical conductivity, self-moistening. Coating ability, etc.), and organic composite coated plates that can meet a variety of use requirements at the same time are developing rapidly.

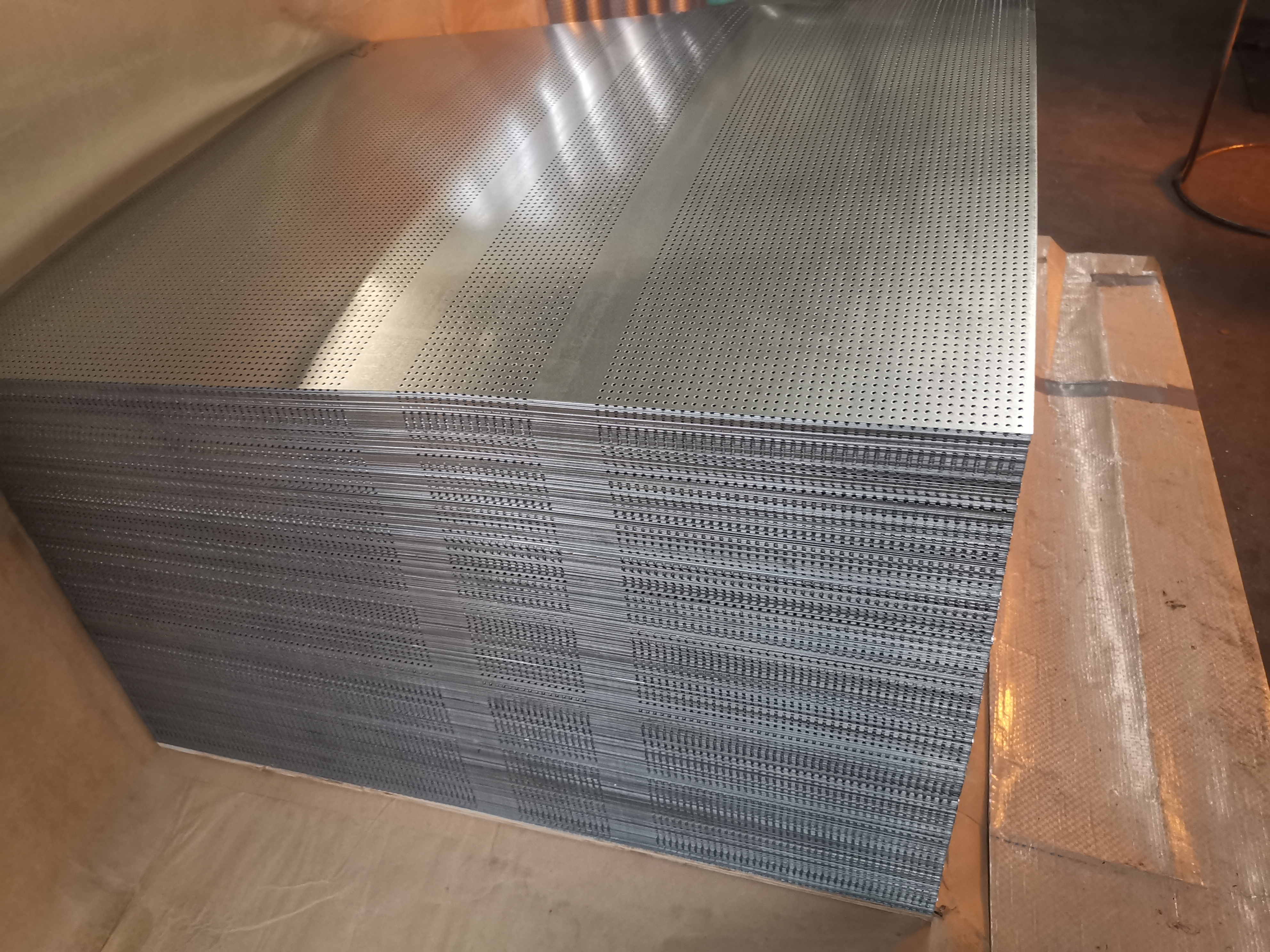

Fingerprint resistant plate can be used to produce expanded metal mesh, perforated metal mesh and filter end caps, if necessary, you can contact us!

CONTACT US

Are you still looking for a stable supplier? If you are still troubled by the communication of quality and details, please contact us—Anping Dongjie Wire Mesh.

Focusing on the wire mesh industry for more than 27 years, we have our own factory and professional team to escort your project!

0086-15930870079

NEED HELP?

Don’t hesitate to ask us something. Email us directly at admin@dongjie88.com or call us at 0086-15930870079.

GIVE US A CALL

As a high-quality Chinese manufacturer with more than 27 years of professional production experience, we will recommend the most suitable solution to you one-on-one according to your needs.

AVAILABLE AT 9AM TO 6PM

Post time: Sep-05-2023