The production process of building climbing net:

1: The mold punching process starts with accurate mold design. We believe that the quality of the mold determines the quality of the product to a large extent. Therefore, in recent years we have invested a lot of money in this area, which has significantly improved our molding capabilities.

2: Punching We have advanced high-speed stamping equipment, which can punch high-quality products. The daily output can reach 2000㎡, and the thickness of the plates that can be punched is between 0.2mm-25mm.

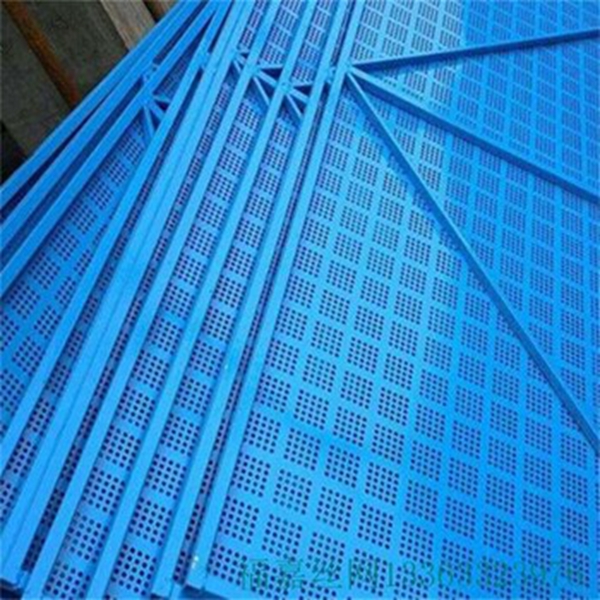

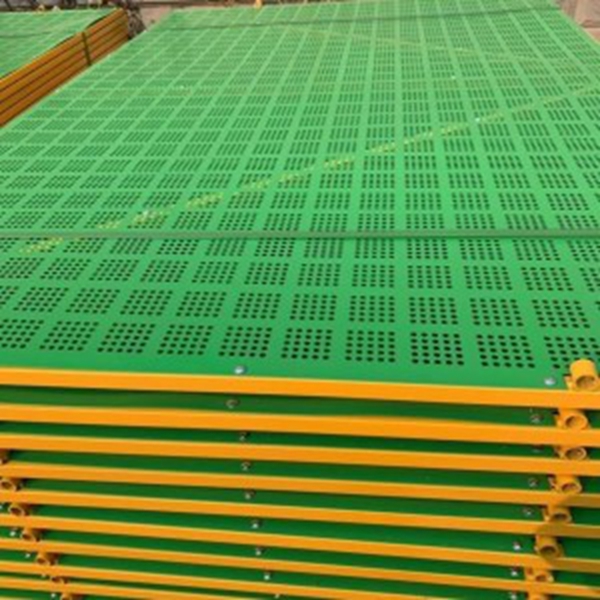

3: Plastic spraying is a surface treatment method that sprays plastic powder on parts. Plastic spraying is what we often call electrostatic powder spraying. Its processing technology is a metal surface treatment decoration technology that has been widely used in the world since the 1980s. Compared with ordinary spray paint surface treatment, the advantages of this technology are reflected in advanced technology, energy saving and high efficiency, safety and reliability, and bright color. Therefore, it is often used in light industry and home decoration fields. Its working principle is to charge the plastic powder through high-voltage electrostatic equipment. Under the action of the electric field, the paint is sprayed onto the surface of the workpiece. The powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating; and the powdery coating passes through After leveling and solidification after high-temperature baking, the plastic particles will melt into a dense final protective coating with different effects; firmly attached to the surface of the workpiece

Perforated climbing frame mesh is a new type of protective net commonly used on construction sites, also known as climbing frame mesh. A protective net with punched metal plates should be made on its surface, mainly to prevent construction workers from safety protection problems during work, commonly known as climbing frames. To put it bluntly, it means that you can climb up, unlike traditional scaffolding, which has to be dismantled and then installed. It is used in the construction protection of high-rise and super-high-rise buildings of various design types and tall buildings with consistent shapes; it is suitable for the construction of complex shapes such as cast-in-situ shear walls, frames, arc balconies, and cantilevers.

Post time: Mar-13-2024