Laser cutting technology uses the energy released when the laser beam is irradiated onto the surface of stainless steel perforated mesh to melt and evaporate the stainless steel. The laser source is generally a carbon dioxide laser beam. The power level is lower than that required by many household electric heaters, but the laser beam is focused on a very small area through lenses and reflectors. The high concentration of energy can quickly heat the area locally, causing the stainless steel to evaporate. Lasers can be used to cut stainless steel perforated meshes of complex shapes very accurately, and the cut stainless steel perforated meshes do not need to be further processed. The price of laser cutting equipment is quite expensive, but since it reduces the cost of subsequent process processing, it is still feasible to use this equipment in large-scale production. Since there is no tool processing cost, laser cutting equipment is also suitable for producing small batches of various sizes of parts that could not be processed before.

Currently, products suitable for laser cutting can be roughly divided into three categories:

Category 1: Metal sheet metal parts that are not suitable for manufacturing molds from a technical and economic perspective, especially those with complex contours, small batches, and generally thick; 12mm low-carbon steel,; 6mm thick stainless steel, in order to save the cost and cycle of manufacturing molds.

The second category: patterns, marks, fonts, etc. of stainless steel or non-metallic materials used in decoration, advertising, and service industries.

The third category: special parts that require uniform slits.

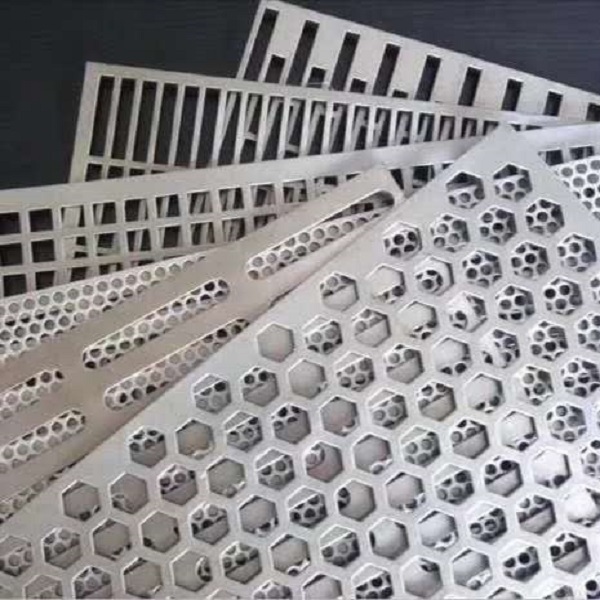

Stainless steel perforated mesh refers to perforated mesh made of stainless steel. There are many advantages of using stainless steel perforated plates, the most important of which are: the mesh surface is flat, smooth, beautiful, strong and durable, and has a wide range of uses.

Uses of stainless steel perforated plates:

1. Used in civil engineering

2. Used for protection of mechanical equipment

3. Used in handicraft manufacturing

4. Used for high-end speaker grilles

5. Used for ventilation and heat dissipation of grain

6. Used as reinforcement for bridges

Post time: Jun-05-2024