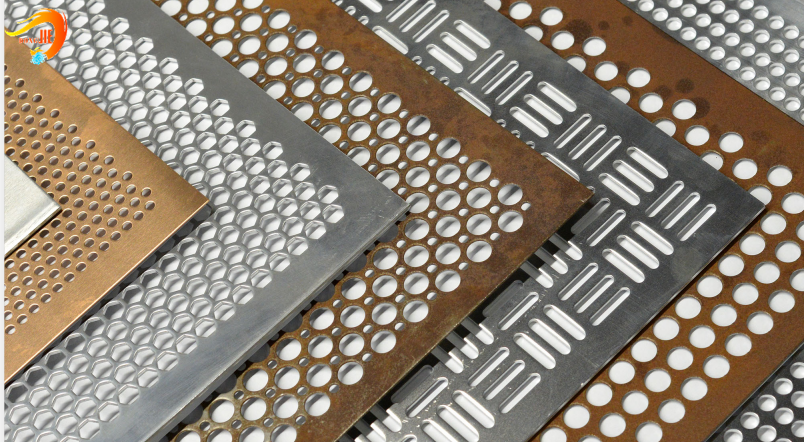

In daily life or industrial use, the product punching plate is increasingly used. The punching plate is produced using a metal plate and a special mold on a CNC punch machine. It can be punched according to needs or drawings. Products come in many shapes or sizes.

Punching plates can be divided into many types of materials. Common steel materials include cold-rolled plates, hot-rolled plates, manganese steel plates, galvanized steel plates, stainless steel plates, aluminum plates, etc.

1. Cold-rolled plate is a plate rolled below the recrystallization temperature. The thickness can be customized from 0.2mm to 4mm, the width is from 600mm to 2000mm, and the length of the steel plate is from 1200mm to 6000mm. Due to the cold-rolled steel plate in the production process No heating is required, so the surface finish is very high and the dimensional accuracy is also very high. The surface anti-corrosion treatment after punching is also very smooth.

2. The surface finish of hot-rolled plates is much rougher than that of cold-rolled plates. Since hot-rolled plates are rolled at high temperatures, they have stronger ductility than cold-rolled plates. When making bending, coils, etc. Perforated plate products that require secondary processing are widely used.

3. Manganese steel plate is a low-alloy high-strength steel plate with a yield value of 345, commonly known as Q345 steel plate. In the punching industry, it is mostly used in mine screens, screen stone mesh and other places. Manganese steel punching plates have very strong resistance. Impact and abrasion resistance.

4. Galvanized steel plate is coated with a layer of metallic zinc to prevent corrosion on the surface of the steel plate and extend the service life of the punched plate. The punched plate made of this kind of plate has better anti-rust effect.

5. Stainless steel plates are mostly used in humid or highly corrosive places in the punching industry. Stainless steel punched plates have stronger corrosion resistance and wear resistance than galvanized plates, but the price is much more expensive than galvanized plates.

6. Aluminum perforated panels are generally used in the decoration industry. For example, if the ceiling is made of aluminum perforated panels, it has a sound-absorbing effect, and the aluminum plate is very light in weight, which can effectively prevent the ceiling from sagging naturally over time.

Post time: Apr-08-2024