There are many kinds of plastering net. Here we will introduce several common plaster mesh, which are mainly used for wall insulation, avoid cracking, hollowing and so on.

1. Welding plaster mesh: the most common, but also a large sales of a product. Plastering welding net is also called plastering welding net. Plastering welded wire mesh is a kind of wire mesh used in building external wall, pouring concrete, high-rise residential buildings, etc., which plays an important role in the insulation system. During the construction, the polystyrene board is placed on the inner side of the external wall formwork to be poured, the external insulation board and the wall survive at one time, and the insulation board and the wall are integrated after the formwork is removed.

The advantages of wall plastering net are that the high-quality low-carbon iron wire is selected for this commodity. After spot welding and forming of automatic and precise mechanical equipment, the external treatment of zinc immersion technology is selected. It is produced by British standard. The net surface is smooth and smooth, the structure is consolidated and the whole function is good. Even if some of the cut-off or pressure is accepted, it is the anti-corrosion in all iron screen The corrosion function is strong, and it is also one of the widely used mesh types of iron screen.

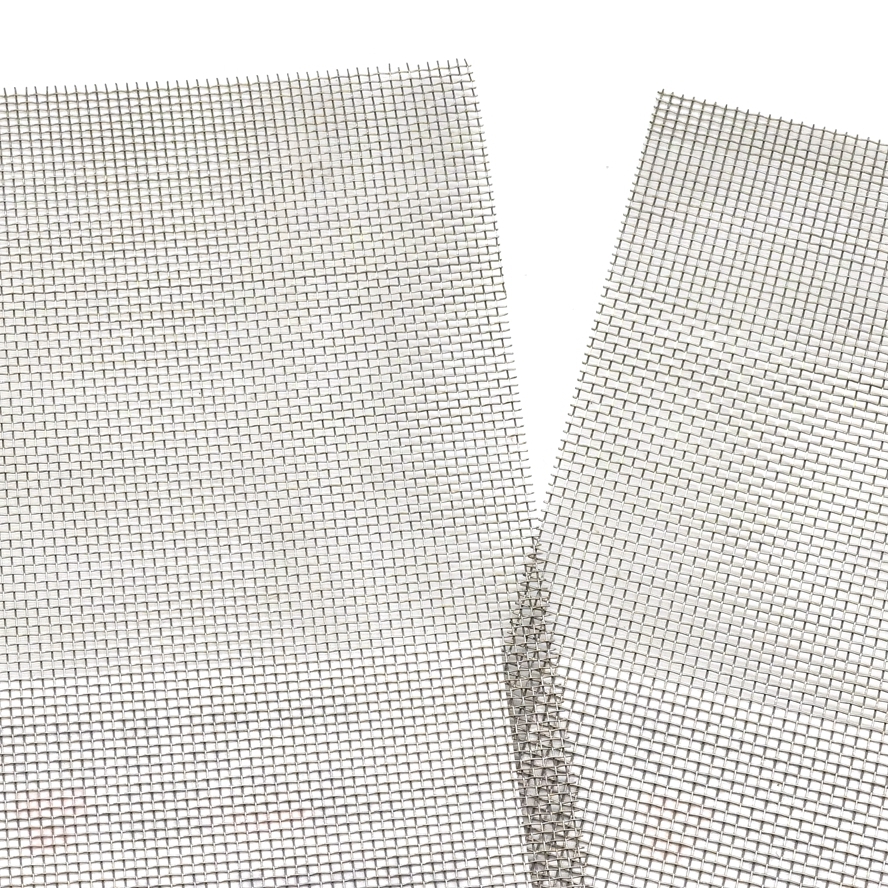

2. Woven Wire Mesh: also known as galvanized mesh, modified drawing mesh, plastering mesh, square eye mesh, mud mesh (2.5 mesh-60 mesh). Lead mesh material: low carbon steel hard bright wire, galvanized wire; lead mesh weaving and features: plain weave. Precise structure, uniform mesh, good corrosion resistance and durability. Characteristics of lead mesh: low price, strong magnetism, precise structure, uniform mesh, good corrosion resistance and durability; types of lead mesh: wave (curl) square mesh, standard square mesh, hot dip electroplating after weaving, square mesh before weaving, square mesh after weaving, electroplating lead mesh. Application of lead screen: it can be pressed into various kinds of filter screen according to the use requirements, and can also be spot welded into multi-layer filter screen with different mesh numbers. It is mainly used for mechanical ventilation protection, rubber work, plastic work, petrochemical industry, grain industry filtration and screening of various ores, gravel and mud. It is widely used in industry and construction, gravel screening, particle screening in industry, mining and construction, medicine screening, ventilation and protection in machinery manufacturing and civil use. Filtering liquid and gas is also used for safety protection of mechanical accessories.

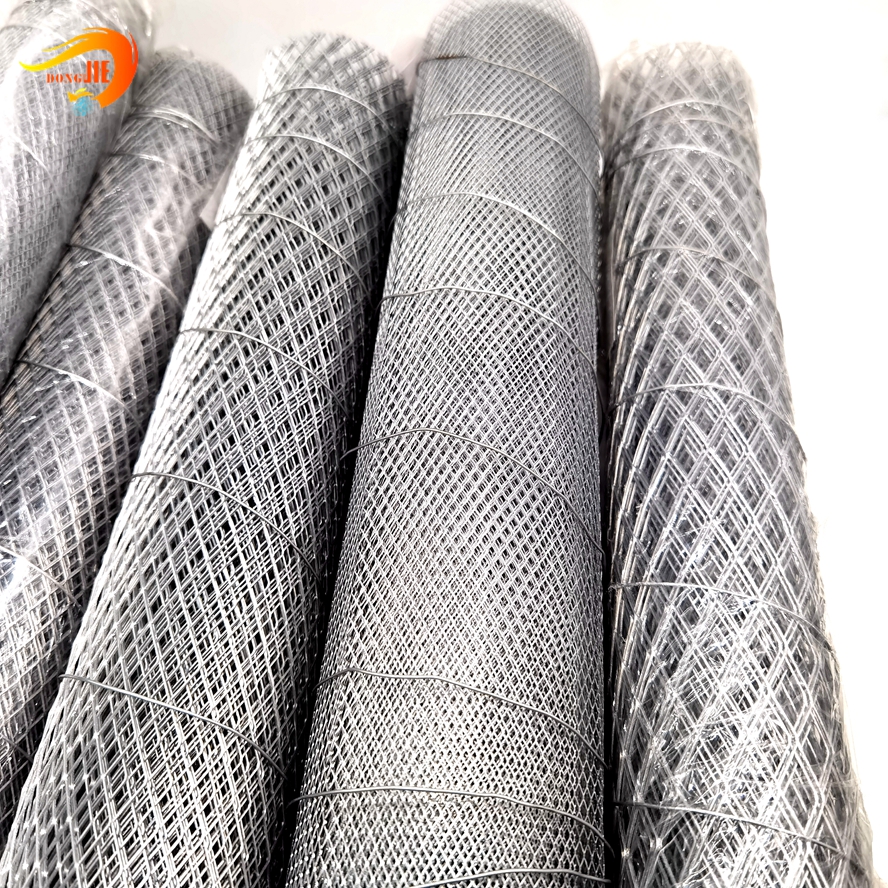

3. Expanded metal steel mesh for plastering is a major application field of steel mesh. It is installed and used in the process of wall plastering. It mainly plays the role of reinforcement and crack prevention. It is a necessary reinforcement metal building material for building walls.

The material of expanded metal mesh for plastering wall: stainless steel or galvanized plate, made by mechanical punching, shearing and stretching.

In the selection of plate, this kind of expanded metal mesh chooses very thin stainless steel plate, the thickness is generally about 0.2mm, which belongs to the product type of very small plate thickness in steel mesh products.

In the selection of mesh, the expanded metal mesh with rhombic hole is usually selected by punching and drawing, because the hole structure of this kind of steel mesh is stable, and the hole density is higher than that of hexagonal steel mesh, which has very good anti cracking performance.

Generally, the diamond hole of expanded metal mesh for plastering wall is of smaller hole size. The LWD of hole is between 10 mm-20 mm, and the SWD is between 5 mm-15 mm. It belongs to steel mesh with smaller hole size.

After the completion of production, the surface is usually painted to increase its acid and alkali corrosion resistance, so that the service life will not be reduced because it is in the alkaline mortar.

Post time: Mar-16-2021