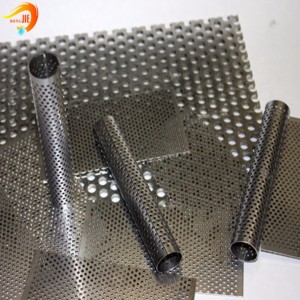

Today, I will introduce a choice of filter cartridges - punching filter cartridges.

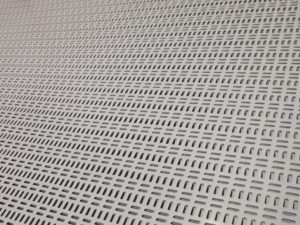

When the perforated metal mesh is used as the filter mesh, the filtering performance is good: the filter particle size of 200um can achieve uniform surface filtering performance;

Specifications

| Product Name | Perforated Metal Cylinder Filter Tube |

| Materials | Low carbon steel, stainless steel of 201, 304, 316, 409, 2250, etc. |

| Thickness | 0.4-15mm or custom |

| Outer Diameter | φ9-1000mm |

| Length | 10-6000mm |

| Hole Size | φ0.5-20mm |

| Hole Pattern | Square, round, diamond, hexagonal, oblong, slot, etc. |

| Surface Treatment | Electropolishing, painting, plastic spraying, etc. |

| Application | Muffler, petroleum production, chemical industry, sewage treatment, purified water treatment,

water filtration, various filter element frameworks, filter components, etc. |

| Packing | In cartons or wooden case |

| Quality Control | ISO Certificates |

Applications

Our products can be used for different filtration, dust removal, and separation needs: chemical industry filtration of chemical raw materials, solid-liquid separation, food processing filtration, oil industry filtration, environmental protection water treatment, air conditioning, purifier, air filter, dehumidifier, dust collector, etc.

About us

Dongjie has adopted ISO9001:2008 Quality System Certificate, SGS Quality System Certificate, and a modern management system. Anping Dongjie Wire Mesh Products Factory is founded in 1996 with over 5000sqm areas.

We have more than 100 professional workers and 4 professional workshops: expanded metal mesh workshop, perforated workshop, stamping wire mesh products workshop, molds made, and deep-processing workshop.

Produce process

Material

Punching

Test

Surface treatment

Final product

Packing

Loading

FAQ

Q1:How to make an inquiry about Perforated Metal Mesh?

A1:You need to provide material, hole size, thickness, sheet size, and the quantity to ask for an offer. You can also indicate if you have any special requirements.

Q2:Could you provide a free sample?

A2:Yes, we can provide a free sample in half A4 size together with our catalogue. But the courier charge will be on your side. We'll send back the courier charge if you make an order.

Q3:How is your Payment Term?

A3:Generally, our payment term is T/T 30% in advance and the balance 70% before shipping. Other payment terms we can also discuss.

Q4:How is your delivery time?

A4:The delivery time is usually determined by the technology and quantity of the product. If it’s urgent for you, we also could communicate with the production department about the delivery time.

We have more than 26 years of production experience, welcome to consult.

Post time: Jul-29-2022