OEM Factory Sheet Metal Fabrication Service Stainless Steel Laser Cutting Welding Bending Stamping Parts

OEM Factory Sheet Metal Fabrication Service Stainless Steel Laser Cutting Welding Bending Stamping Parts

Product Description

Stamping parts are a forming processing method that relies on presses and molds to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, thereby obtaining workpieces (stamping parts) of the required shape and size. Stamping and forging both belong to plastic processing (or pressure processing), and are collectively called forging.

Stamping is mainly classified according to process and can be divided into two categories: separation process and forming process. The separation process is also called blanking. Its purpose is to separate the stamping parts from the sheet along a certain contour line while ensuring the quality requirements of the separated section. The surface and internal properties of stamping sheets have a great influence on the quality of stamped products. The thickness of stamping materials is required to be accurate and uniform; the surface is smooth, no spots, scars, scratches, no surface cracks, etc.; the yield strength is uniform and has no obvious Directionality; high uniform elongation; low yield-to-strength ratio; low work hardening.

Company Profile

ANPING COUNTY DONGJIE WIRE MESH PRODUCTS CO., LTD

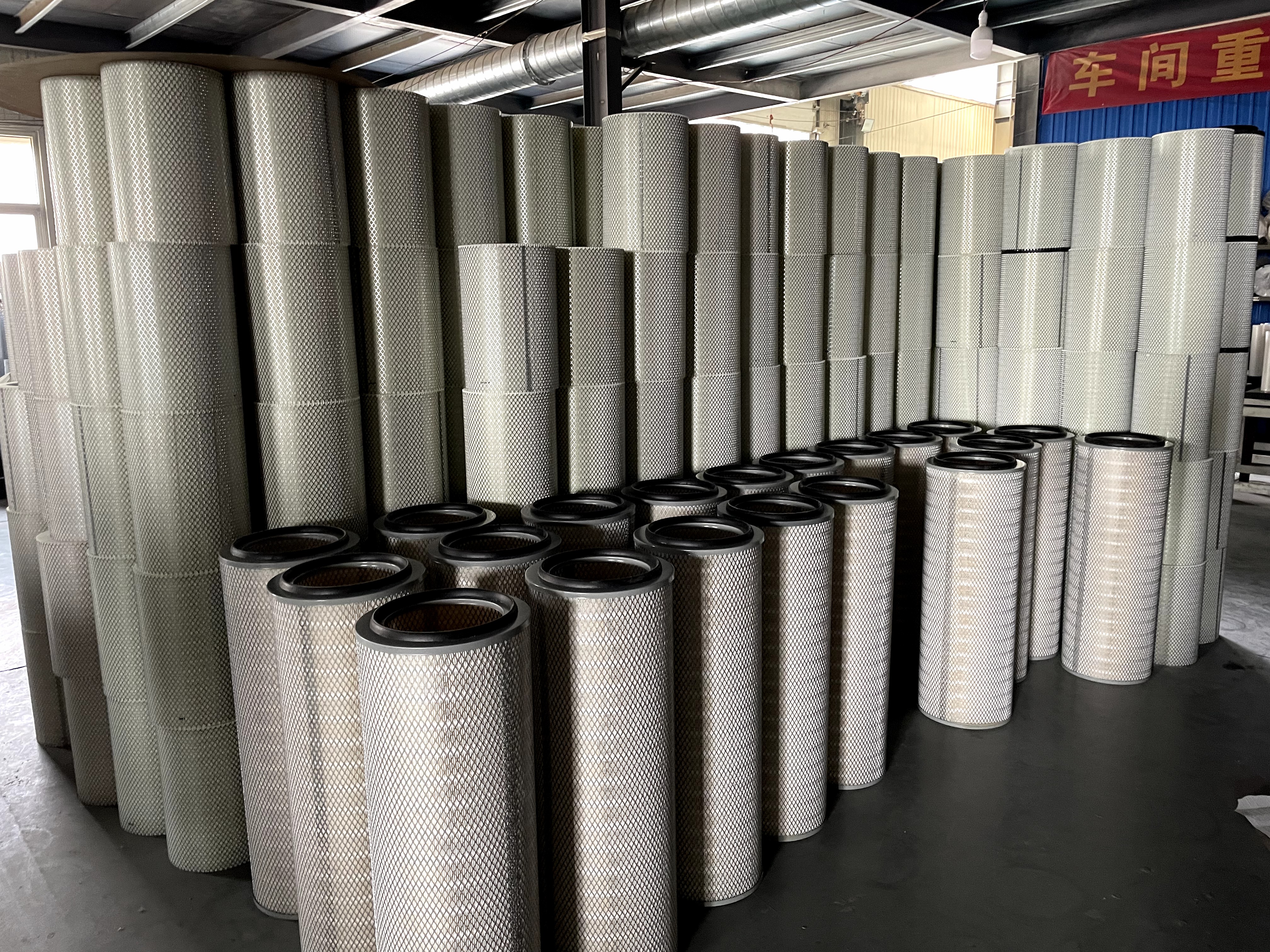

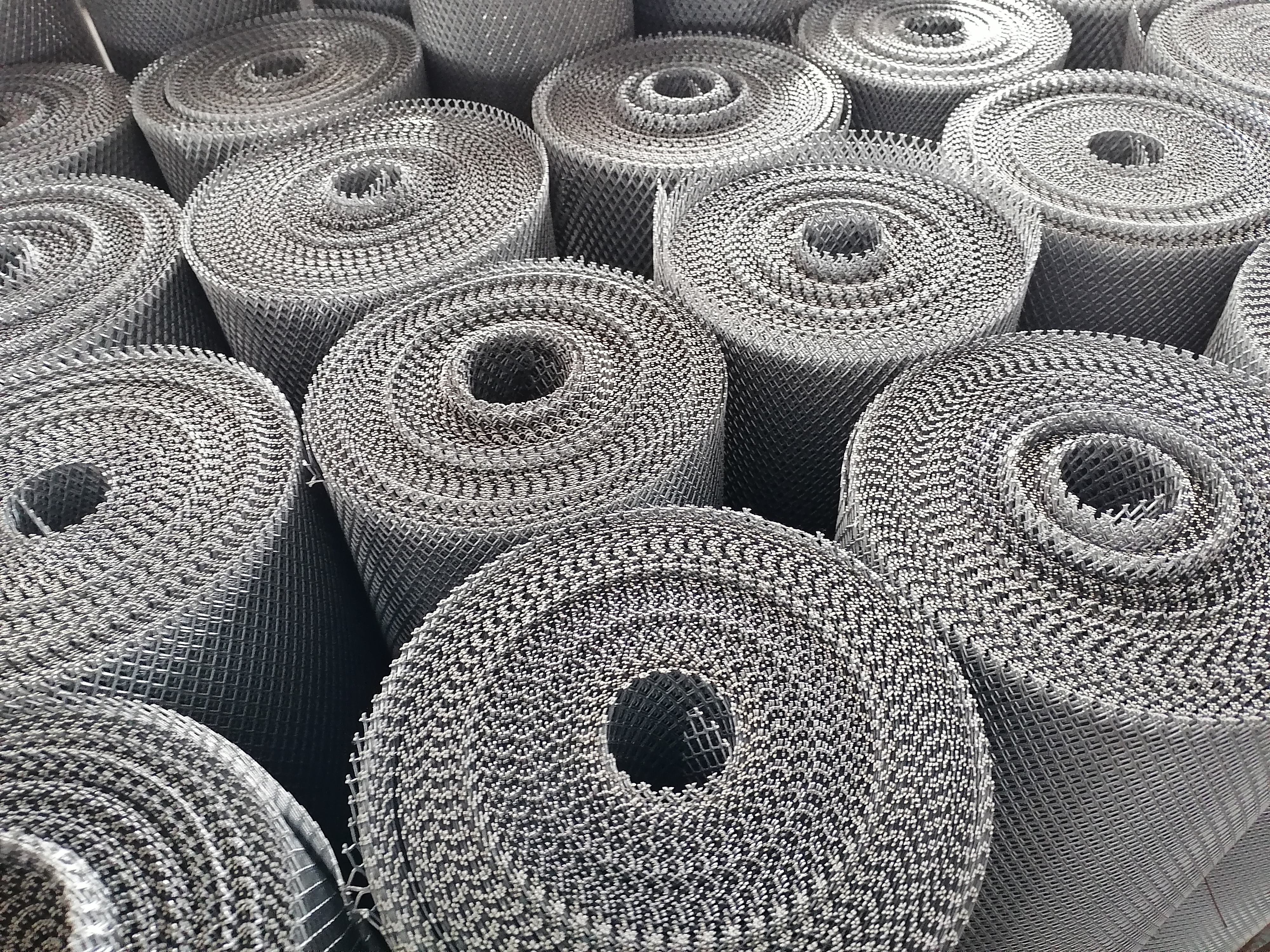

Anping Dongjie Wire Mesh Products Factory is founded in 1996 with 5000sqm areas. We have more than 100 professional workers and 4 professional workshops: expanded metal mesh workshop, perforated workshop, stamping wire mesh products workshop, molds made, and deep-processing workshop.

Our Skills & Expertise

We are a specialized manufacturer for the development, design, and production of expanded metal mesh, perforated metal mesh, decorative wire mesh, filter end caps and stamping parts for decades. Dongjie has adopted ISO9001:2008 Quality System Certificate, SGS Quality System Certificate, and a modern management system.

If you need it, just click the button below.

ANPING DONGJIE WIRE MESH PRODUCTS CO., LTD

Q1: Are you a manufacturer or a trader?