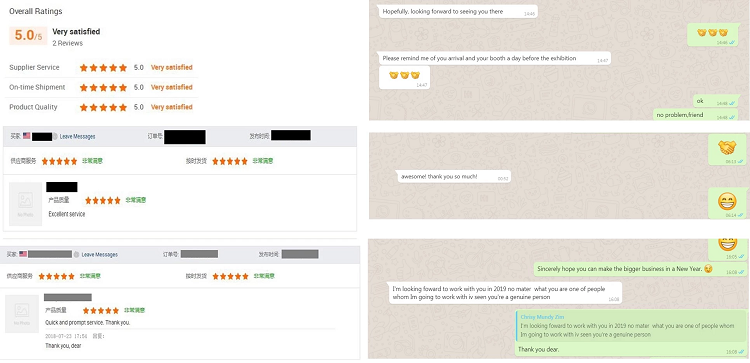

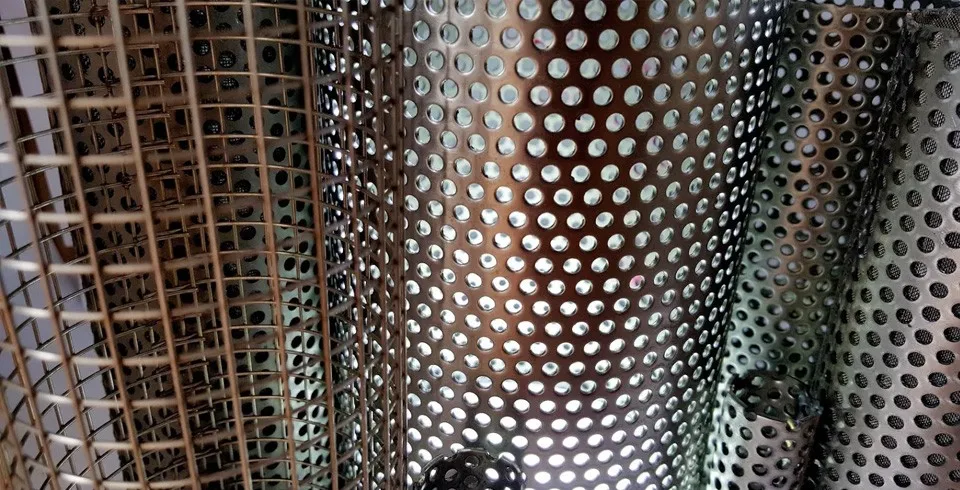

Various Sizes Perforated Metal Sheet Facade Cladding

How is perforated metal made?

The manufacturing process for perforating metal starts with sheet metal. Sheet metal is thin and flat, and can be cut and bent into different shapes. In many area of the world, sheet metal thickness is measured in millimeters.

The most common method of perforating metal uses a rotary pinned perforation roller. This is a large cylinder with sharp, pointed needles on the outside to punch holes into the metal. As the sheet metal is run across the perforation roller, it rotates, continuously punching holes in the passing sheet. The needles on the roller, which can produce a wide variety of hole sizes, are sometimes heated to simultaneously melt the metal which forms a reinforced ring around the perforation.

Another common method is “die and punch” perforating. During this process, a sheet with needles is repeatedly pressed onto the passing metal which punches holes into the sheet. The pieces remaining from the punching are then sheared off and the surface is smoothed. The die and punch method is very efficient and can perforate a large surface of sheet very quickly.

Perforated Metal Technology

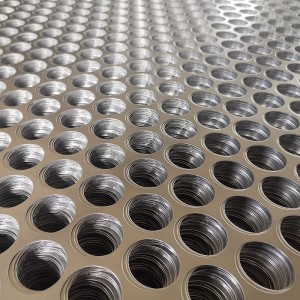

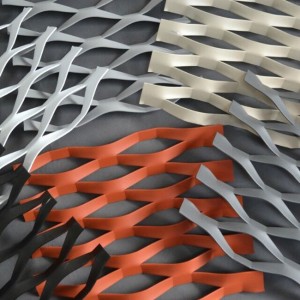

1. Perforated metals are very popular in contemporary architecture as they lend themselves to creative and unique designs.

2. Sun protection and climate control: Perforated metal sheets are excellent at providing rooms with air flow and shade, often used as sun protection screens in rooms that require ventilation. Although they appear to be a design element, their permeable nature allows the free movement of air, resulting in substantial energy savings on heating, ventilation and air conditioning.

3. Noise reduction: Perforated metal sheets are often used for noise reduction walls and roof systems. In noisy environments, they can limit the adverse effects of noise on workers’ health.

4. Balustrade screening panels: Perforated metal sheets are used in panels for balconies, staircase, and balustrades screens. They offer weather resistant protection coupled with an attractive design.

5. Automotive: Used for oil filters, radiator grilles, running boards, engine ventilation and motorcycle silencers.

Bulk loading in the container or Customer requirements.

We will serve every detail process, provide fast delivery guarantee and perfect after-sales service to ensure your every purchase is satisfied.

ANPING DONGJIE WIRE MESH PRODUCTS CO., LTD

Q1: Are you a manufacturer or a trader?